Rieter’s Set Of Combing Machines Achieves Highest Standards Of Productivity In The World

The company’s technological advantage is based on optimal interaction between machine and technology, company sources said. According to company sources, there are various technological and economic advantages in using Rieter’s set of combing machines.

Rieter’s E 36 OMEGAlap is the most economical combing machine, the company said, adding that an increase in production of 20% to over 600 kg/h at a constant speed of upto 230 m/min has been achieved. At such a high production rate, the OMEGAlap is far superior to conventional machines, company sources said.

The influence of the OMEGAlap on the economic performance of a unit’s combing section is enormous. The high production allows a reduction in the number of preparatory machines, which noticeably reduces the number of can changes, while fewer personnel are needed, according to company sources.

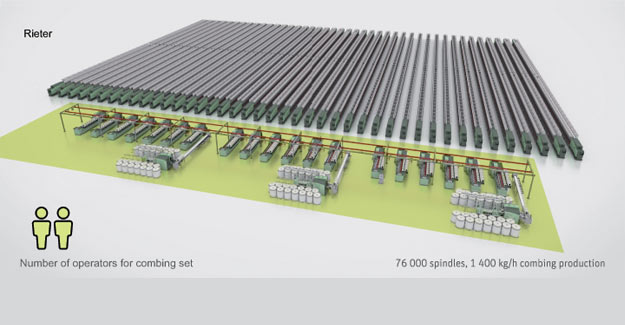

As an example, the company stated personnel requirement calculations for a combing set in a compact spinning facility with 76,000 spindles. Compared to other machine manufacturers, personnel requirement could be reduced by three workers, the company stated.

This is realised by efficient combing preparation, the SERVOlap fully automated lap transport system as well as the comber including the ROBOlap automated lap changing and piecing system (Figure 1 and Figure 2).

Reduction of personnel needed for the combing preparation machine can be up to 20 workers and it leads to reduced manufacturing costs by approximately US$ 190,000?per year, the company stated. The strength of the E 86 comber lies in a high level of cleaning as well as excellent running performance, with high nip rates. The E 86 achieves fewer imperfections in the yarn (thin places, thick places, neps) at the same noil removal level compared to combers made by other manufacturers. The high degree of cleaning has no effects on fibre quality, which means that fibre length remains unchanged and thus yarn tenacity remains at a high level (Figure 3).

Also, the E 86 attains an improved dust and trash elimination of up to 20 %. The short fibre content, the hairiness as well as the evenness in the yarn remain unchanged (Figure 5), according to the company.

Both these examples cited prove that a higher cleaning effect is achieved by means of stronger combing intensity without compromises in the combing quality, the company stated.

The company cited another example from Southeast Asia which showed better yarn quality with the E 86, compared to results received from another manufacturer. At the same production performance and the same noil removal, the company claimed that imperfections were found to be lower by 40% (Figure 6).

Raw material is a considerable cost factor in spinning mills. With the E 86, noil removal can be reduced by up to 1% at equally good yarn quality (Figure 7) and this generates cost savings of up to US$ 55,000 annually, the company stated citing an example from Central Asia.

Production performance also positively affects the costs of the spinning mill. The E 86 has the potential to achieve a 10% higher production compared to the previous model, at the same noil removal and yarn quality (Figure 8). This corresponds to a saving in manufacturing costs of about US$ 20,000 per year and combing set, the company stated, citing an example from Turkey.

The E 86 comber, with its high production at simultaneously high quality, leads the way in combing. Individual quality demands can be realised thanks to high-value technology components.

The established, fully-automated ROBOlap lap changing and piecing system is the standard for a modern combing facility. Together with the unique OMEGAlap preparation, the highest production per set on the market has been achieved, the company stated.

Textile Excellence

If you wish to Subscribe to Textile Excellence Print Edition, kindly fill in the below form and we shall get back to you with details.