Inspiron Brings Advanced Textile Stenter Motex 15000 With New Features To India ITME

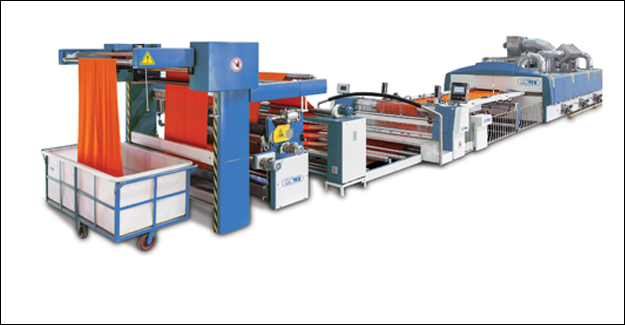

Hot air textile stenter manufacturer InspirOn Engineering Pvt Ltd plans to showcase its next generation stenter, the Motex 15000, at India ITME India in hall 5, stall C1,the company has announced.

Compared to its earlier model Motex 4560, the new model consumes less energy, has better safety features, minimises waste, while offering better operational efficiency and maximum return on investment, according to a company release.

The Motex 15000, while also being manufactured in a sustainable manner, has been developed with unprecedented features and state-of-the-art aesthetics.

As against the Motex 4560, the new model Motex 15000 offers 15% higher drying efficiency and higher operating speed. The stenter enables the processor to achieve even drying and heat setting at higher evaporation rates with optimum energy utilisation, which translates into lower operating cost per metre of fabric.

The Motex 15000 also achieves consistent and reproducible results across the length and width of the fabric, even with larger overfeed adjustment range up to 80%. It ensures higher stretch, irrespective of the higher GSM of the fabric and is equipped with pin protection flapper for knitted fabrics.

The stenter requires lubrication once a year or even later, while offering easy access and retrieval of operating and maintenance manual through graphic user interface. Its higher squeezing capability ensures optimum pick up percentage for specific processes like wet on wet finish with desired add on, resulting in better productivity. It comes equipped with a tilting trough with optimised capacity to reduce drain losses.

Recently, InspirOn unveiled a research and development (R&D) centre near Ahmedabad, which will undertake sustainable development projects to produce products of the best quality, innovative and user friendly technology, to meet and preferably surpass customer expectations.

Attached to the R&D centre is also an incubation centre, which is equipped with a demo stenter for mills to undertake trails and test out their unique ideas, while also validating them under actual working conditions, before venturing into commercial production.

The incubation centre is equipped with a laboratory, library and conference cum training room and is manned by a team of process technologists and design professionals.

The vision behind setting up the R&D centre as well as the incubation centre include offering value added services to the customer, demonstration of new features as well as standardisation of process parameters for various substrate on customer request.

The vision also includes acting as an effective link between emerging needs of customers and identifying newer scopes for R&D, while also providing services related to process optimisation assignment, technical consultation as well as performance evaluation.

Textile Excellence

If you wish to Subscribe to Textile Excellence Print Edition, kindly fill in the below form and we shall get back to you with details.