Investment In Industrial Yarn Projects Continues, Oerlikon Barmag remains the leading supplier of production systems

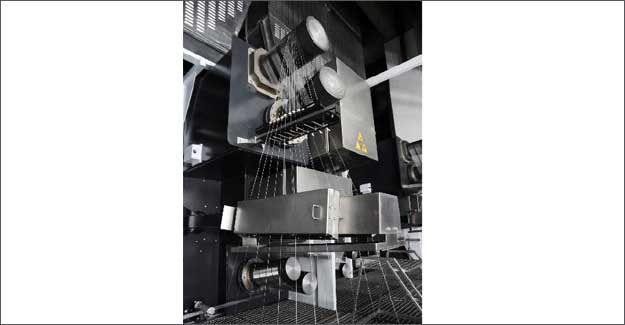

The Remscheid-based Oerlikon Barmag who secured an above-average number of industrial yarns projects in 2015, confirms that the trend of investment in industrial filament continues. This shows the sustainable success of the company’s comprehensive range of innovative process solutions offered for the industrial yarn production process. Oerlikon Barmag is and has been a leading partner and a solutions provider of efficient ‘from-melt-to-yarn’ production processes for several decades.

The new industrial yarn systems that will be commissioned in this year are mostly from the Asian region; however, manufacturing industrial yarn is also an interesting business proposition for producers in Europe due to the high margins and specialized areas of application it offers. “We are experiencing huge demand for industrial yarn systems. Customers are asking for products that offer better margins, such as specialties and industrial yarns, for example”, says Oliver Lemke, Regional Sales Director at Oerlikon Barmag.

Stefan Becker, Senior Expert, Research and Development, adds “What has been very well received by our customers is that our current machine concepts for industrial fine-denier nylon yarns. This allows us to offer configurations that are specifically tailored to the product requirements of the end application of these yarns, such as tents, tarpaulins, parachutes, etc. Here, the focus of the machine design is both on the product quality of the yarns in typical denier ranges of between 20 and 70 denier and on production efficiency and, above all, on the optimization of the conversion costs.”

The major portions of the production of polyester and polyamide industrial yarns from the new plants find application in the automotive sector (airbags, safety belts, tire cord). Also, some yarns are find application in geotextiles and products for textile construction. Also the trend of polyester yarns as a substitute for polyamide remains prevalent among many product categories such as airbags. This is due to the consistently improving properties of polyester with considerably lower raw material costs. Despite all this, the market for industrial yarns continues to diversify and develop very much in line with the specific end applications. Here, the growing demand for high-performance tires is resulting in increased demand for both PET HMLS yarns and of PA66 yarns for use as ‘cap ply’.

Oerlikon Barmag offers product quality-oriented machine solutions that efficiently cover the end application requirements with excellent conversion costs for all product categories. Already, systems for manufacturing PET and PA yarns for airbags, tires and safety belts are successfully operating in the automotive sector, while there are also systems being used for textile applications such as upholstery and carpets.

Textile Excellence

If you wish to Subscribe to Textile Excellence Print Edition, kindly fill in the below form and we shall get back to you with details.