It Was A Fulfilling Roundup For LMW At ITMA Asia Shanghai

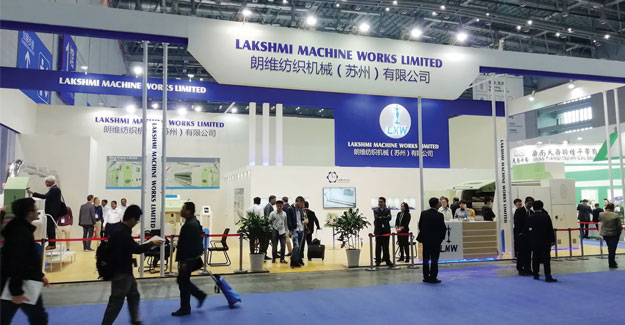

ITMA Asia + CITME 2018 was held during 15 to 19 October at the new National Exhibition Convention Centre (NECC) in Shanghai. This is one of the global textile exhibition held in Chine every alternate years. At the recently concluded ITMA Asia + CITME 2018 in Shanghai, Lakshmi Machine Works participated and displayed its industry-leading range of machines that include: Card LC636, Drawframe LDF3, Comber LK69 machines and SPINPACT - the Suction compact system. There were also live demonstrations of the company's technology platform for its leading range of textile machines - SPINCONNECT along with the entire range of LMW components for the spinning industry on display. LMW's Comber LK69 and Drawframe LDF3 were demonstrated at 600 Nips per minute and at 550 mpm respectively for cotton-combed process. The SpinConnect was displayed with live data from one of LMW's premier customers in China. LMW's display of key components included spindles, compact retrofit models, YBS and RSM models, rings, fluted rollers, cots and aprons. Also, other key components - speedframe, comber, drawframe and carding machines were exhibited. Customers were able to have indepth interactions with LMW's team. New features galore At ITMA Asia 2018, LMW brought to the forefront, the new features that have been incorporated in LMW Comber LK69 machine: Servo drives for drafting, which enables main draft adjustments through digital display, and a hank correction facility that helps achieve better CV%. The comber machine on display was fitted with an inverter-controlled main motor that enables effortless change of machine speeds through the display facility itself. LMW Drawframe LDF3 displayed two new features: A separate drive for coiler, which helps in better coiling and self-adjustment of coiling speed to suit the filling type. Fan motors with inverter help achieve effective and optimum suction for different processes. Even the aesthetically re-designed doors and covers of LDF3 drew wide appreciation from the visitors. LMW's Card LC636 with 1.5 metres of working width for maximum utilisation, and SpinConnect integration were well received at the event. The new age manufacturing yields top-in-line quality and improved precision for long lasting value. LMW's latest offerings in advanced automation capabilities and digitization were also well-received by the industry. Great feedback, a testimony to quality and service LMW was able to meet a wide customer base from China and other countries in the region. LMW received good number of enquiries for its various technology solutions. The overwhelmingly positive response at the show reinforces the company’s plans of further expansion in China and other emerging markets.

Textile Excellence

If you wish to Subscribe to Textile Excellence Print Edition, kindly fill in the below form and we shall get back to you with details.