The Steam Challenge - How To Make The Best Out Of Older Drum Dryers

Maintaining the running cost of a plant at a low level is often the difference between profit and loss. By saving the excess energy which is normally wasted during the drying process on a drum dryer, the mill profits twice: In the first place by the simple savings of energy; and secondly, by maintaining a constant moisture level. The latest Mahlo Atmoset shows how.

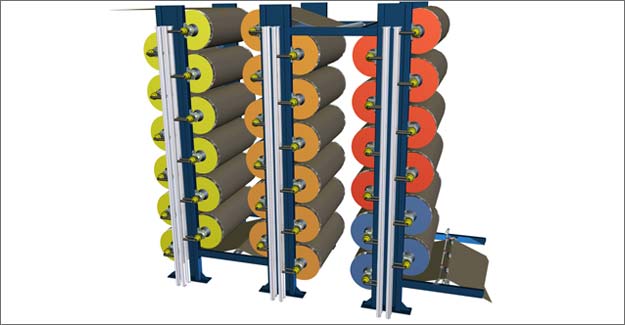

When integrating a drum dryer into a continuous open width range (Pre-treatment, Washing, Mercerizing, Pad Steam…) it’s always the highest speed combined with the heaviest fabric that determines the number of drums. In many cases- especially at older installations- there’s no opportunity for any control of this process. This meansthe production process of every fabric- no matter how light it is –runs with the same drying capacity.

The result: a constant waste of steam and over-dried fabric. But what does this mean in particular? Let us focus on the steam consumption first. With a given potential of the boiler house, the drum dryer needs to share the source of the steam production with many other machines on the production floor: dyeing machines, washing machines, steamers. They all require energy. Especially on a Monday morning the different production units are fighting for the first place in the battle for steam whilst heating up. This is exactly the time when the first production loss of the week takes place: When the dyeing machines cannot heat up fast enough because all the steam is consumed by an oversized drum dryer.

Once the dryers have reached the operating temperature, the next problem occurs: every piece of fabric, no matter which weight, will get the same amount of heat- most of the time, too much of it. As a result, a lot of over-dried fabric will end up in the trolley or the A-frame behind the dryer. As cylinder dryers mainly are used for cotton fabric, the hygroscopic properties of the cotton fibre are kicking in. This means, the over-dried fibre is getting back moisture from the environment. The normal water content of cotton is 8.5%; if exposed to a very moist environment, this value may even rise. Consequently, the outer layers of the fabric on the A-frame or the trolley may have moisture of probably 10%, whilst the core of the batch still remains over-dried with 0% residual moisture.

The problem becomes evident once the next padding step takes place. Between the outer layers of a lot and the layers near the core, there may be a gap of 10% residual moisture, if the process has not been controlled. If padding softeners or other auxiliaries, this situation only leads to a waste of chemicals; but if a Cold Pad Batch application takes place after the uneven drying, this will result in an uneven dyeing for sure.

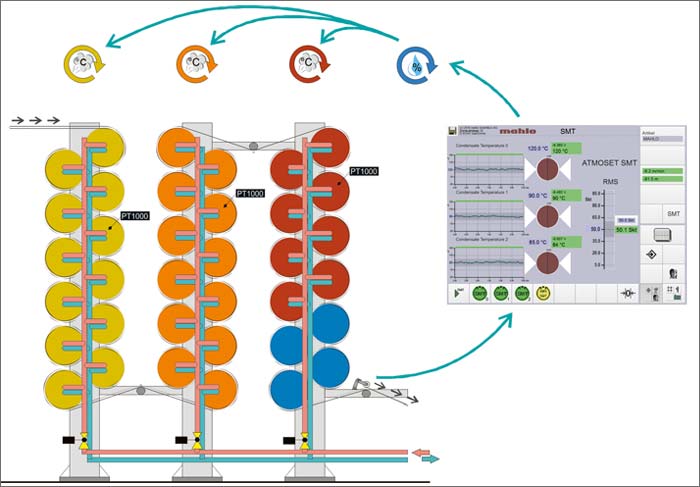

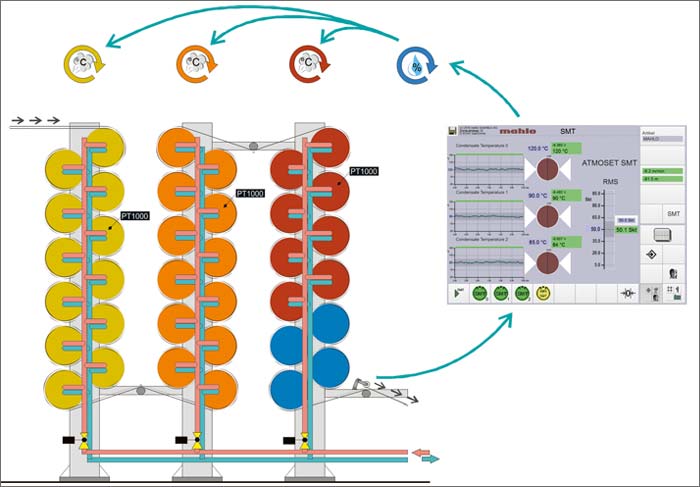

Summary: Having a controlled moisture management at the cylinder dryer is not only saving a lot of expensive energy, it also serves the aim for a constant and reliable production output, with lower fabric seconds. A closed loop between the residual moisture of the fabric and the performance of the different cylinders therefore makes a lot of sense and can help to save a lot of money. And that is exactly what the Mahlo Atmoset accomplishes.

Once the dryers have reached the operating temperature, the next problem occurs: every piece of fabric, no matter which weight, will get the same amount of heat- most of the time, too much of it. As a result, a lot of over-dried fabric will end up in the trolley or the A-frame behind the dryer. As cylinder dryers mainly are used for cotton fabric, the hygroscopic properties of the cotton fibre are kicking in. This means, the over-dried fibre is getting back moisture from the environment. The normal water content of cotton is 8.5%; if exposed to a very moist environment, this value may even rise. Consequently, the outer layers of the fabric on the A-frame or the trolley may have moisture of probably 10%, whilst the core of the batch still remains over-dried with 0% residual moisture.

The problem becomes evident once the next padding step takes place. Between the outer layers of a lot and the layers near the core, there may be a gap of 10% residual moisture, if the process has not been controlled. If padding softeners or other auxiliaries, this situation only leads to a waste of chemicals; but if a Cold Pad Batch application takes place after the uneven drying, this will result in an uneven dyeing for sure.

Summary: Having a controlled moisture management at the cylinder dryer is not only saving a lot of expensive energy, it also serves the aim for a constant and reliable production output, with lower fabric seconds. A closed loop between the residual moisture of the fabric and the performance of the different cylinders therefore makes a lot of sense and can help to save a lot of money. And that is exactly what the Mahlo Atmoset accomplishes.

Textile Excellence

If you wish to Subscribe to Textile Excellence Print Edition, kindly fill in the below form and we shall get back to you with details.