Mixing Silk With Polymers Could Lead To Better Biomedical Implants

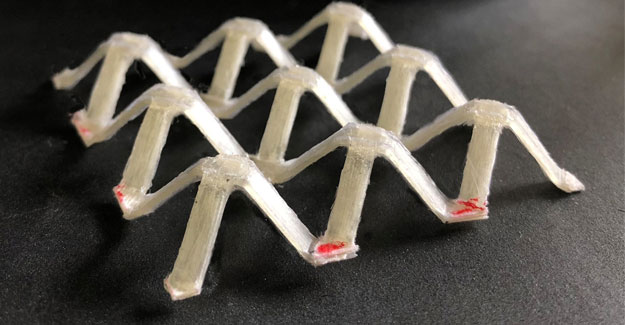

Spun by spiders and silkworms, silk has mystified human engineers who have yet to figure out how to artificially recreate this tough, fine fibre. But by combining silk, which is safe for use in the human body, with synthetic compounds, one research team is getting closer to developing new implantable composite materials with the best properties of both. Potential applications, which are still years away, could include structures that hold bone in place after surgery or replacements for the cartilage cushions in the knee. The researchers presented their results at the American Chemical Society (ACS) Fall 2020 Virtual Meeting & Expo. "Silk has great potential for use in biomedical applications," says Juan Guan, Ph.D., the project's principal investigator. "Silk is versatile, and the human body tolerates it quite well, and can even degrade and absorb it." Silk has a long history in medicine. Records of ancient doctors stitching up patients with fibres spun by silkworms date back nearly 2,000 years. And today, surgeons finish certain surgeries, such as those on the eye, with silk sutures. By combining silk and synthetic polymers, Guan and her colleagues at Beihang University are seeking to develop versatile new materials for use in medicine and, potentially, other fields as well. While other researchers have already developed composite materials with silk, they have typically worked with short fibres or the primary protein in silk. Guan, however, focuses on silk fabric woven from a long, single thread. Silkworms' cocoons can contain fibres nearly 5,000 feet long, and when used whole in fabric, such a fibre can more effectively distribute mechanical stress than a series of shorter, discrete ones, she says. In their studies, Guan's team uses silk from the common, domesticated silkworm Bombyx mori, as well as tougher, more stretchy fibres from the wild species Antheraea pernyi. The researchers combine this fabric with a polymer matrix, often an epoxy, which is used in adhesives. Together, the fabric and the polymer form a laminate -similar to the durable surface covering found on some furniture - which can then be cut into the shapes the researchers need. Guan and her colleagues say that the properties of these new materials could make them a better match for the tissues within the human body than what is being used today. For instance, they are collaborating with orthopedic doctors to devise structures resembling cages that temporarily hold vertebrae in place as they fuse after surgery, a task currently accomplished mostly using metal. The silk composites' hardness and stiffness is more compatible with bone, making them potentially more resilient yet more comfortable than metal structures, she says. There are challenges, however. The inside of the human body is moist, a potential problem because water can soften and weaken silk. In new experiments, Guan and her colleagues tested how silk-epoxy composite materials hold up when exposed to humidity or immersed in water. For use alongside bone, they must maintain a certain stiffness. The experiments showed that while this attribute decreased under wetter conditions, the composites remained stiff enough to function as implants, she says. While the epoxy attaches firmly to the silk fibre, it has a major drawback: The body can't break down the epoxy and absorb it, meaning it would not be suitable for implants intended to dissolve. So, Guan recently began working with biopolymers that, like silk, the body can break down and absorb. However, these composites have less internal cohesion than those that contain an epoxy. "The key question is how to make the interface between the biopolymer and the silk fabric more robust," she says. The scientists are also looking to supplement silk with other types of fibres. In a recent study, they added carbon fibres into the mix. "The notion of hybridizing silk with other fibres makes it possible to produce a rather nice spectrum of properties that you can optimise for a given application," says Robert O. Ritchie, Ph.D, an author of the carbon fibre study. Potential uses for these new structural materials, he says, could be anywhere: in the human body, or even in tennis rackets or on airplane engines.

Textile Excellence

If you wish to Subscribe to Textile Excellence Print Edition, kindly fill in the below form and we shall get back to you with details.