Using Rieter Systems For Sustainable Yarn Production

Minimum environmental pollution, maximum power consumption savings, optimum use of resources: These are just some of the factors that Rieter has considered for decades when developing new products. The spinning systems offer customers sustainable yarn production and long-term profitability.

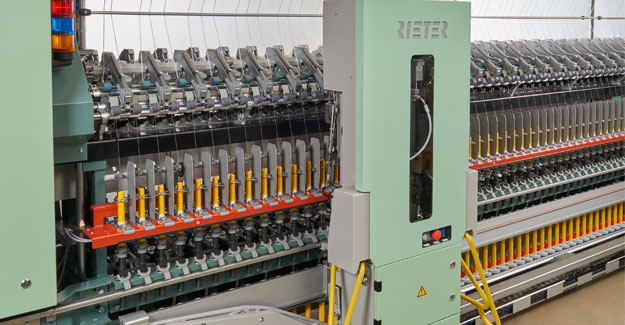

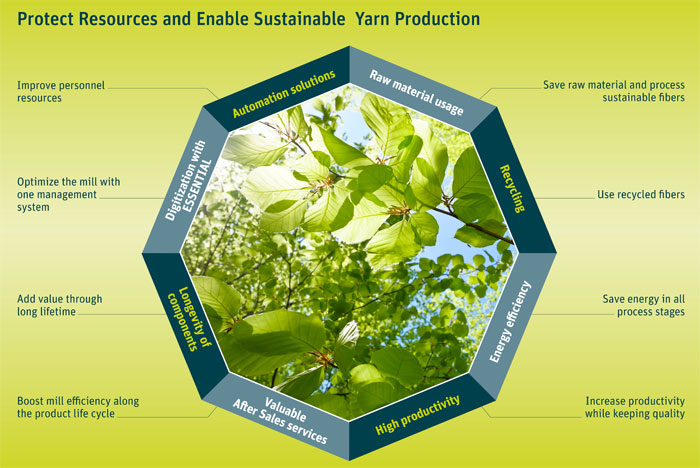

When developing sustainable machines, systems, and services, Rieter considers the entire life cycle of the machines. The focus here is on saving energy and optimum use of resources, as well as efficient and economical production to remain competitive (Fig. 1).

[caption id="attachment_21127" align="alignnone" width="700"] Rieter machines and services enable sustainable yarn production. (Fig 1)[/caption]

Sustainable raw material utilisation

Rieter spinning technologies ensure good utilisation of raw materials, which can optimise fibre consumption. Rieter systems can be used to process bast fibres or recycled fibres into rotor yarns or ring yarns. These types of fibre are playing an increasingly important role in yarn production. Rieter is driving these innovative solutions for the sustainable use of raw materials.

[caption id="attachment_21126" align="alignright" width="350"]

Rieter machines and services enable sustainable yarn production. (Fig 1)[/caption]

Sustainable raw material utilisation

Rieter spinning technologies ensure good utilisation of raw materials, which can optimise fibre consumption. Rieter systems can be used to process bast fibres or recycled fibres into rotor yarns or ring yarns. These types of fibre are playing an increasingly important role in yarn production. Rieter is driving these innovative solutions for the sustainable use of raw materials.

[caption id="attachment_21126" align="alignright" width="350"] Rieter offers a spinning process that cottonizes bast fibres and produces high-quality rotor yarns. (Fig 2)[/caption]

Rieter offers customized, economical solutions for preparing bast fibres such as flax or hemp for short-staple spinning mills (Fig. 2). Preparation is an important precondition for spinning the bast fibres. For the preparation process, Rieter cooperates with the German company Temafa. The machines enable fibres to be extracted from straw bales. The fibres are shortened and refined until they are similar to cotton fibres in length and fineness. This process is called cottonizing. The prepared fibres are best spun using a rotor spinning machine. Rotor yarn offers advantages over ring yarn in terms of elongation, hairiness, and downstream processing.

[caption id="attachment_21125" align="alignleft" width="300"]

Rieter offers a spinning process that cottonizes bast fibres and produces high-quality rotor yarns. (Fig 2)[/caption]

Rieter offers customized, economical solutions for preparing bast fibres such as flax or hemp for short-staple spinning mills (Fig. 2). Preparation is an important precondition for spinning the bast fibres. For the preparation process, Rieter cooperates with the German company Temafa. The machines enable fibres to be extracted from straw bales. The fibres are shortened and refined until they are similar to cotton fibres in length and fineness. This process is called cottonizing. The prepared fibres are best spun using a rotor spinning machine. Rotor yarn offers advantages over ring yarn in terms of elongation, hairiness, and downstream processing.

[caption id="attachment_21125" align="alignleft" width="300"] Rieter spinning systems offer solutions to produce ring and rotor yarns from recycled fibres. (Fig 3)[/caption]

Ring and rotor yarns made from recycled fibres

Today, only 1% of the world’s clothing is recycled, with 73% ending up in landfill. In addition to this, recycled clothes are currently reused mainly in lower-value products. Higher expectations from consumers and technological advances are changing this. The results of the latest Rieter study show that it is possible to spin not only rotor yarns but also ring yarns of varying quality with up to 75% post-consumer materials – i.e., regenerated fibres from old clothes (Fig. 3). The resulting yarn is of a sufficiently high

[caption id="attachment_21124" align="alignright" width="174"]

Rieter spinning systems offer solutions to produce ring and rotor yarns from recycled fibres. (Fig 3)[/caption]

Ring and rotor yarns made from recycled fibres

Today, only 1% of the world’s clothing is recycled, with 73% ending up in landfill. In addition to this, recycled clothes are currently reused mainly in lower-value products. Higher expectations from consumers and technological advances are changing this. The results of the latest Rieter study show that it is possible to spin not only rotor yarns but also ring yarns of varying quality with up to 75% post-consumer materials – i.e., regenerated fibres from old clothes (Fig. 3). The resulting yarn is of a sufficiently high

[caption id="attachment_21124" align="alignright" width="174"] More information about processing recycled fibres is available on the Rieter website under the topic “Textile Technology Know-How.” (Fig 4)[/caption]

quality to use in the weaving and knitting processes and to manufacture products of a similar quality to those made from virgin fibres. Possible end applications include jeans, work clothes, T-shirts, and chinos. The study also scrutinized the economic aspects. Depending on the yarn count, spinning technology, and percentage of recycled fibres, a return on investment (ROI) can be achieved within three to five years. More information can be found in the technology publication “The Increasing Importance of Recycling in the Staple-Fibre Spinning Process” (Fig. 4) https://l.ead.me/bbi405

Maximum energy efficiency

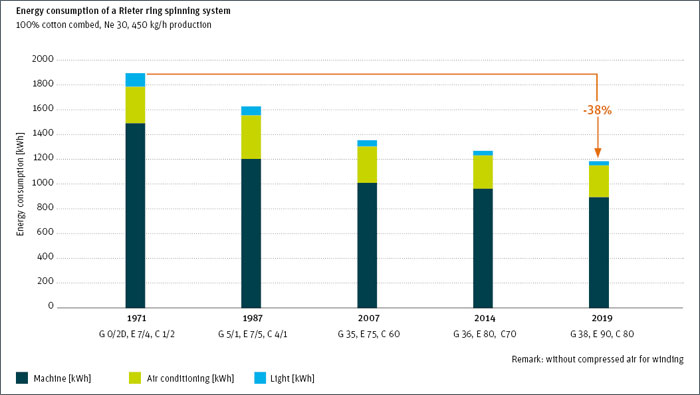

Energy consumption is a significant cost factor in yarn production. Every small energy saving counts for customers and for the sustainability of their company. Whichever spinning system customers decide on, all Rieter machines and systems contribute to energy efficiency. The biggest consumers of energy are end-spinning machines. For this reason, Rieter has been focusing on possible energy savings during the development of its end-spinning machines for many years. However, Rieter is also aiming to reduce the energy consumption per kilogram of yarn produced whenever it develops a new model of other types of machine. Therefore, clear energy savings have been achieved in Rieter systems over the last few decades (Fig. 5). To distinguish the systems, only the most important machines are listed in the image in the following order: ring spinning machine, comber, card.

[caption id="attachment_21123" align="alignnone" width="700"]

More information about processing recycled fibres is available on the Rieter website under the topic “Textile Technology Know-How.” (Fig 4)[/caption]

quality to use in the weaving and knitting processes and to manufacture products of a similar quality to those made from virgin fibres. Possible end applications include jeans, work clothes, T-shirts, and chinos. The study also scrutinized the economic aspects. Depending on the yarn count, spinning technology, and percentage of recycled fibres, a return on investment (ROI) can be achieved within three to five years. More information can be found in the technology publication “The Increasing Importance of Recycling in the Staple-Fibre Spinning Process” (Fig. 4) https://l.ead.me/bbi405

Maximum energy efficiency

Energy consumption is a significant cost factor in yarn production. Every small energy saving counts for customers and for the sustainability of their company. Whichever spinning system customers decide on, all Rieter machines and systems contribute to energy efficiency. The biggest consumers of energy are end-spinning machines. For this reason, Rieter has been focusing on possible energy savings during the development of its end-spinning machines for many years. However, Rieter is also aiming to reduce the energy consumption per kilogram of yarn produced whenever it develops a new model of other types of machine. Therefore, clear energy savings have been achieved in Rieter systems over the last few decades (Fig. 5). To distinguish the systems, only the most important machines are listed in the image in the following order: ring spinning machine, comber, card.

[caption id="attachment_21123" align="alignnone" width="700"] Over the last few decades, Rieter has reduced energy consumption for the production of combed cotton ring yarn by 38%. (Fig 5)[/caption]

Reducing ecological footprint

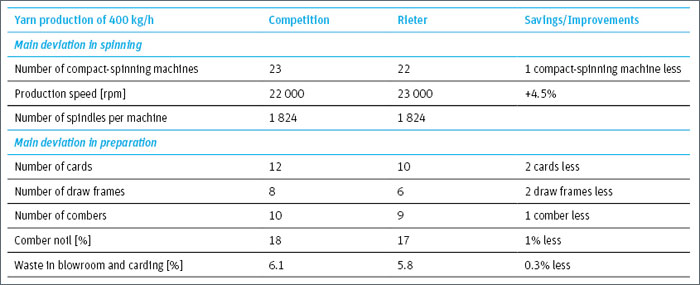

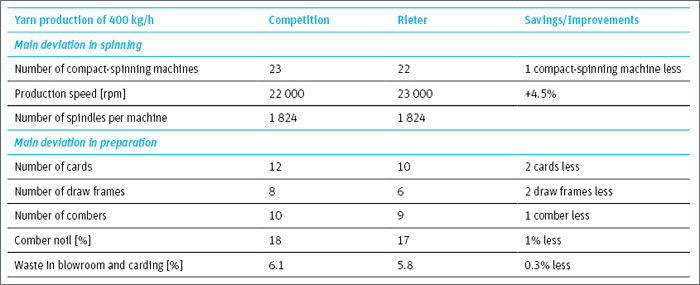

Rieter machines produce the same quantity and the same high quality using fewer machines. The example below shows the advantage of a Rieter compact-spinning system compared to a system consisting of machines from different manufacturers (Fig. 6). The Rieter system produces the same quantity of yarn using fewer machines and with less waste, reducing the ecological footprint of the spinning mill. A particularly important factor is that the yarn quality produced using the Rieter system is the same as when using comparable systems.

[caption id="attachment_21122" align="alignnone" width="700"]

Over the last few decades, Rieter has reduced energy consumption for the production of combed cotton ring yarn by 38%. (Fig 5)[/caption]

Reducing ecological footprint

Rieter machines produce the same quantity and the same high quality using fewer machines. The example below shows the advantage of a Rieter compact-spinning system compared to a system consisting of machines from different manufacturers (Fig. 6). The Rieter system produces the same quantity of yarn using fewer machines and with less waste, reducing the ecological footprint of the spinning mill. A particularly important factor is that the yarn quality produced using the Rieter system is the same as when using comparable systems.

[caption id="attachment_21122" align="alignnone" width="700"] Production with fewer machines and less waste positively impacts the ecological balance. (Fig 6)[/caption]

Customer services can also increase the productivity and efficiency of the system. Services such as performance optimization, preventive maintenance packages, customer training, upgrades, and repairs can also help prolong the service life of existing products.

Mill assessments are one option for optimizing performance. The way to achieve such optimizations is simple: Experts analyse the situation at the customer’s spinning mill and offer suggestions for process or machine optimization, replacing wear parts, recommended conversions, and optimizing workflows. This is how Buhler Yarns Inc., a leading supplier of fine yarn in Jefferson, Georgia (USA) began collaborating with Rieter. The entire spinning mill underwent a detailed mill assessment lasting several days. In the scope of this collaboration, machine settings were optimized, particularly in the blowroom and combing section, and existing machines were upgraded. This led to a 4% raw-material saving on cotton, a 2% saving on special fibres, a 30% improvement in yarn imperfections, and finally, a 6% increase in productivity. Production costs have also been reduced and the production skills of employees have been strengthened. The costs for this process have been recuperated in less than 18 months. The investment is also contributing to the competitiveness and sustainability of the spinning mill.

Numerous further possibilities

Rieter also offers modernisations for existing products. The compacting device COMPACTdrum for ring spinning machines is a clever solution for spinning compact yarns. After it has been installed for the first time, the compacting device is easy to install and remove, making it possible to quickly switch between ring yarn and compact yarn. The piecing robot ROBOspin for ring spinning machines and compact-spinning machines increases machine availability and therefore productivity (Abb. 7), as the piecing process is automated in the event of ends down during spinning or after doffing. ROBOspin ensures consistently high piecing quality and works around the clock without losing efficiency. This also applies to all other automation options, such as the lap transport system SERVOlap in the combing section and the roving bobbin transport system SERVOtrail. This saves on personnel, who can therefore be deployed more effectively in a different role. Resources are used more efficiently.

Sustainable yarn production thanks to digitalisation

Around the world, digitalisation is playing an increasingly important role and making a significant contribution to advances in sustainability. The digital spinning mill platform ESSENTIAL continuously monitors the entire process chain and quickly highlights inefficiencies. This allows personnel to be deployed more efficiently. Recording specific production, energy, and quality data ensures fast response times and increases the efficiency of spinning mills, while also reducing costs. Tracking the sustainability footprint of a spinning mill is also supported.

Rieter offers the most suitable products, systems, and services for saving resources and producing sustainable yarn, combined with high yarn quality and competitiveness. This ensures that the spinning mill achieves long-term, sustainable success.

Production with fewer machines and less waste positively impacts the ecological balance. (Fig 6)[/caption]

Customer services can also increase the productivity and efficiency of the system. Services such as performance optimization, preventive maintenance packages, customer training, upgrades, and repairs can also help prolong the service life of existing products.

Mill assessments are one option for optimizing performance. The way to achieve such optimizations is simple: Experts analyse the situation at the customer’s spinning mill and offer suggestions for process or machine optimization, replacing wear parts, recommended conversions, and optimizing workflows. This is how Buhler Yarns Inc., a leading supplier of fine yarn in Jefferson, Georgia (USA) began collaborating with Rieter. The entire spinning mill underwent a detailed mill assessment lasting several days. In the scope of this collaboration, machine settings were optimized, particularly in the blowroom and combing section, and existing machines were upgraded. This led to a 4% raw-material saving on cotton, a 2% saving on special fibres, a 30% improvement in yarn imperfections, and finally, a 6% increase in productivity. Production costs have also been reduced and the production skills of employees have been strengthened. The costs for this process have been recuperated in less than 18 months. The investment is also contributing to the competitiveness and sustainability of the spinning mill.

Numerous further possibilities

Rieter also offers modernisations for existing products. The compacting device COMPACTdrum for ring spinning machines is a clever solution for spinning compact yarns. After it has been installed for the first time, the compacting device is easy to install and remove, making it possible to quickly switch between ring yarn and compact yarn. The piecing robot ROBOspin for ring spinning machines and compact-spinning machines increases machine availability and therefore productivity (Abb. 7), as the piecing process is automated in the event of ends down during spinning or after doffing. ROBOspin ensures consistently high piecing quality and works around the clock without losing efficiency. This also applies to all other automation options, such as the lap transport system SERVOlap in the combing section and the roving bobbin transport system SERVOtrail. This saves on personnel, who can therefore be deployed more effectively in a different role. Resources are used more efficiently.

Sustainable yarn production thanks to digitalisation

Around the world, digitalisation is playing an increasingly important role and making a significant contribution to advances in sustainability. The digital spinning mill platform ESSENTIAL continuously monitors the entire process chain and quickly highlights inefficiencies. This allows personnel to be deployed more efficiently. Recording specific production, energy, and quality data ensures fast response times and increases the efficiency of spinning mills, while also reducing costs. Tracking the sustainability footprint of a spinning mill is also supported.

Rieter offers the most suitable products, systems, and services for saving resources and producing sustainable yarn, combined with high yarn quality and competitiveness. This ensures that the spinning mill achieves long-term, sustainable success.

Textile Excellence

If you wish to Subscribe to Textile Excellence Print Edition, kindly fill in the below form and we shall get back to you with details.