Fabrocia Craftex Develops Plant Leaf Fibre In Its Varanasi Cluster

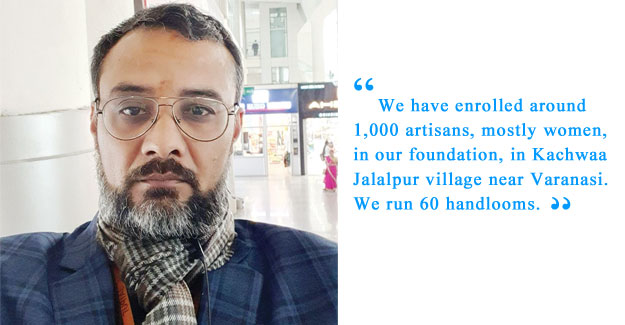

Tell us about your company and your journey in sustainable textiles? Our company, Fabrocia Craftex has been founded by me and my partner Amietobh Mehra. Both of us are hardcore textile professionals. Eventually, we decided to come together and work for the betterment of the handloom sector. My stint in the carpet industry had led me to visit the villages in the country which had these clusters of handlooms. While it was great to see the artisans working and preserving our traditional crafts, we were also appalled at the condition of the weavers. Most clusters were closed or working partially. There were no regular orders. The middleman earns the most and the weavers hardly earn anything. So we started our trust by the name Green Artsy Craftex Foundation. The aim of the foundation is to promote the handloom sector and its artisans and weavers. We want to promote Indian handlooms to all known brands in India and abroad. Fabrocia Craftex is the commercial arm of the foundation. We have enrolled around 1,000 artisans, mostly women, in our foundation, in Kachwaa Jalalpur village near Varanasi. We also provide training sessions to the weavers. We run 60 handlooms. We are exploring government schemes, etc for ramping up production. Tell us in detail all about the PLF fiber that you have used in your latest collection? Being a textile engineer, I was always interested in extraction of fibre from natural sources. During my frequent visits to the villages, I explored the nature of certain leaves which were fibrous and have a good tendency of converting to fibre. I managed to create a beautiful fibre by combining leaves of three different plants. We termed this as PLF (Plant Leaf Fiber ). We use this for creating fabrics both for the apparel and home textiles. What makes your textiles sustainable? Sustainability is a concept mostly confused with natural fibres. Whereas sustainability is a much wider subject. We believe in product and social sustainability. Our products are natural, innovative and our processes are environmentally and even more importantly, socially sustainable. Our products are made without the use of electricity, from fibre to the raw fabric stage. We can dye the fabric naturally too, but our final customers prefer to dye/print the fabric themselves. What kind of environmental certifications have you acquired? We run clusters which are not currently certified. But we are in the process of getting it certified from the Handloom Council.

Textile Excellence

If you wish to Subscribe to Textile Excellence Print Edition, kindly fill in the below form and we shall get back to you with details.