SMIT-ONE: The Best Rapier Technology For Woven Techtex Applications

In the past few years, woven fabrics manufactured on rapier looms have comprised a significant part of the total production of technical textiles, especially for applications such as agro textiles, airbags, canvas fabrics, car seats, coating fabrics, conveyor belts, gauze, geo-grids, filter fabric, fiberglass fabric, tire cord, etc. SMIT srl, a globally renowned weaving machine manufacturing company from Italy with more than 80 years of history, has been supplying advanced rapier looms for technical textile applications. A.T.E. – committed to supporting the Indian textile industry with the latest technology solutions – has recently joined hands with SMIT for the promotion of their rapier looms in India. The partnership between these two textile engineering leaders is expected to provide a fillip to the Indian technical textile segment. SMIT was recognised for the development of the well-known dynamically controlled rapier ribbon system in the late ‘80s, which was the most significant development of the guideless carbon punched tape technology. The philosophy of innovation at SMIT is evident in its new, revolutionary weaving machine – the SMIT-ONE– a patented single rapier weft transfer weaving machine for the manufacture of technical textiles. Key features of the SMIT-ONE:

- SMIT-ONE gripper system has a smaller cross section that complies with the warp shed geometry, which is narrower compared to a traditional double gripper machine

- Weft insertion at low weft tension, resulting in higher insertion efficiency

- Reduced warp shed amplitude, thus increasing efficiency

- Easy to adjust machine during article change, reducing machine downtime

- Can use all yarn types that were so far not weavable on traditional rapier systems – such as delicate yarns, fancy yarns, carbon yarns, etc.

- Special pliers that perfectly hold any weft shape, weight, and consistency

- Laser stop motion, or full-width temple can be offered

- PosiLeno® system: positively controlled leno system which ensures perfect leno binding; is applicable for all fabric constructions including technical fabrics

- Reinforced backrest structure increases warp tension by more than 50%, thus enabling the production of heavy density technical fabrics

- Special type of pressure rollers prevents slippage of cloth on take-up roller

- Stronger sley bar enables production of dense fabrics on the machine

- Take-up designed for ultra-high warp tension

- Working width – 1700 mm to 2200 mm

- Weaver beams up to 1100 mm and fancy beam can be used

- Fabrics for technical, fashion, furnishing applications, as well as classic fabrics with exclusive yarns and patterns, can be woven with excellent quality and high efficiency on the SMIT-ONE

- SMIT’s “dynamically controlled” flexible free-flight tape rapiers system, combined with the development of advanced solutions enhances the weft insertion

- The highest versatility and efficiency in terms of weft insertion allows the use of a wide range of yarns, and unparalleled simplicity in the article change, as well as minimum maintenance costs

- Free flight technology - no friction on the warp yarn

- Minimum stress on warp

- Consistent fabric properties from full to empty warp beams

- Laser warp stop motion to avoid friction on the warp ends

- Special type of full width temple for low cloth recoiling or high weft density

- Fashion fabrics

- Safety gear

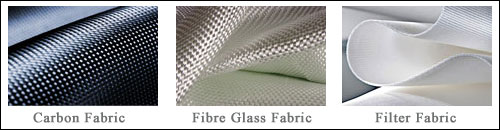

- Glass fabrics

- Carbon fabrics

- Filter fabrics

- Sportswear

- Sophisticated clothing and furnishing

- Suitable to produce fabrics in which complicated yarns are used

Further, SMIT-ONE offers highest versatility, efficiency in terms of weft insertion, flexibility with the widest range of fabrics, and energy savings.

Due to these numerous benefits, SMIT-ONE is emerging as a preferred choice for weavers around the world to meet the rising demand for technical textiles.

Further, SMIT-ONE offers highest versatility, efficiency in terms of weft insertion, flexibility with the widest range of fabrics, and energy savings.

Due to these numerous benefits, SMIT-ONE is emerging as a preferred choice for weavers around the world to meet the rising demand for technical textiles.

Textile Excellence

If you wish to Subscribe to Textile Excellence Print Edition, kindly fill in the below form and we shall get back to you with details.