Rieter’s R 37 Ensures 20% Less Imperfections With Economical Blend

The R 37 is Rieter’s latest semi-automated rotor spinning machine and has proved itself to be the perfect machine for recycled cotton applications as the trash extraction process can be adapted to the raw material. With this machine, the Rieter customer Longgang Deao Industrial Co. Ltd. based in China has achieved a stable higher production as well as improved yarn tenacity and fewer imperfections.

The new spinning box technology makes the semi-automated rotor machine R 37 unique as it allows for flexible adaption to the raw material. Thanks to the replaceable trash channels, a higher level of trash extraction is achieved. The optimised fibre flow in the spinning box results in higher yarn tenacity and fewer imperfections.

[caption id="attachment_21948" align="alignnone" width="614"] The semi-automated rotor spinning machine R 37 is well suited for recycled cotton applications.[/caption]

The R 37 is designed for high production volumes and is more productive than other semi-automated rotor spinning machines available on the market: With the latest rotor spinning technology and up to 600 highly productive spinning units, the R 37 produces yarn at a delivery speed of up to 200 m/min.

Longgang Deao expands in the recycled cotton yarn market

Longgang Deao Industrial Co., Ltd. is a manufacturer of recycled cotton yarn located in Longgang County, Wenzhou, China. It mainly produces Ne 8 to Ne 16 rotor yarns from recycled cotton and viscose. Due to the competitive market situation, Longgang Deao continuously has to optimise its raw material costs and improve quality to meet the expectations of downstream customers. The company’s goal is to expand its share in the recycled cotton yarn market and to further strengthen strategic collaboration with established brands. To achieve this, Longgang Deao invested in five Rieter rotor spinning machines R 37 with a total of 2 600 rotors.

[caption id="attachment_21949" align="alignleft" width="242"]

The semi-automated rotor spinning machine R 37 is well suited for recycled cotton applications.[/caption]

The R 37 is designed for high production volumes and is more productive than other semi-automated rotor spinning machines available on the market: With the latest rotor spinning technology and up to 600 highly productive spinning units, the R 37 produces yarn at a delivery speed of up to 200 m/min.

Longgang Deao expands in the recycled cotton yarn market

Longgang Deao Industrial Co., Ltd. is a manufacturer of recycled cotton yarn located in Longgang County, Wenzhou, China. It mainly produces Ne 8 to Ne 16 rotor yarns from recycled cotton and viscose. Due to the competitive market situation, Longgang Deao continuously has to optimise its raw material costs and improve quality to meet the expectations of downstream customers. The company’s goal is to expand its share in the recycled cotton yarn market and to further strengthen strategic collaboration with established brands. To achieve this, Longgang Deao invested in five Rieter rotor spinning machines R 37 with a total of 2 600 rotors.

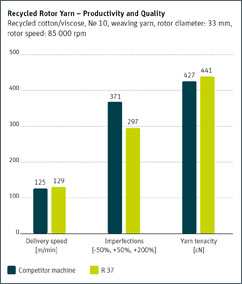

[caption id="attachment_21949" align="alignleft" width="242"] With the R 37, Longgang Deao has reduced imperfections by 20%.[/caption]

20% fewer imperfections in economical blends

At Longgang Deao, the R 37 has shown that it can remove more trash than other machines, all while retaining valuable long fibres in the yarn production process. This has significant advantages: higher productivity, improved yarn tenacity and a 20% reduction in imperfections, mainly neps. This shows that competitive yarn qualities can be achieved from economical blends with a high proportion of waste or recycled fibres. In addition, the R 37 offers high spinning stability and enables the customer to further improve productivity and yarn quality.

Satisfied customers in downstream processing

The considerably improved trash extraction and fibre yield at Longgang Deao meant more good fibres were retained in the spinning process and more short fibres were in the waste, which also led to advantages in downstream processing. Firstly, less dust was created in the subsequent process steps, reducing stops and thus also reducing the workload for the operating personnel. Secondly, the finished fabrics achieved a more attractive appearance.

Zongnao Zhou, General Manager of Longgang Deao, states: “We believe that the R 37 is the most advanced semi-automated rotor spinning machine in the world. The fabrics are more even, and efficiency at the weaving mill is higher. Our customers in downstream processing are more satisfied than ever with Deao products.”

Despite its very high rotor speed, the R 37 has a low energy consumption. This is possible thanks to the highly efficient main drives and an efficient suction system. Longgang Deao reported a 10% lower energy consumption of the R 37 compared to the competition.

Easy operation thanks to perfect machine height

Operating personnel not only benefit from the R 37’s high level of productivity, but also from its ergonomic height. This simplifies operator tasks during piecing and doffing. During the AMIspin piecing process, each step is monitored electronically: Once the operating personnel has properly prepared the yarn ends and inserted them into the exit tube, the process starts automatically after the spinning box is closed. This exactly reproducible process forms the basis for consistent piecing quality, which can be monitored with the yarn clearer and leads to noticeably trouble-free downstream processing.

Doffing of entire machine is twice as fast

The ergonomic of operation jointly with the perfect height of the machine also allows a much faster doffing. According to feedback from customers, only around half the time is required to doff the entire machine R 37 in comparison to other similar machines – even when working with large cans. All important components are directly and easily accessible to the operating personnel and are logically arranged from top to bottom. This ensures better monitoring and results in consistently good yarn quality.

The new optional ROBOdoff can automatically replace the full packages with prepared empty tubes without interrupting the spinning process. This simplifies the arduous task of manual doffing. ROBOdoff can use the information when a package is full and ensures that there is a sufficient transfer tail on the new tube.

All of these features make the R 37 the perfect solution for spinning mills that want to benefit from flexibility when selecting raw materials, high productivity, low energy consumption and optimal conditions for operating personnel. The innovative spinning box technology with adaptable trash extraction system ensures competitive yarn quality, even when using cost-effective raw materials.

With the R 37, Longgang Deao has reduced imperfections by 20%.[/caption]

20% fewer imperfections in economical blends

At Longgang Deao, the R 37 has shown that it can remove more trash than other machines, all while retaining valuable long fibres in the yarn production process. This has significant advantages: higher productivity, improved yarn tenacity and a 20% reduction in imperfections, mainly neps. This shows that competitive yarn qualities can be achieved from economical blends with a high proportion of waste or recycled fibres. In addition, the R 37 offers high spinning stability and enables the customer to further improve productivity and yarn quality.

Satisfied customers in downstream processing

The considerably improved trash extraction and fibre yield at Longgang Deao meant more good fibres were retained in the spinning process and more short fibres were in the waste, which also led to advantages in downstream processing. Firstly, less dust was created in the subsequent process steps, reducing stops and thus also reducing the workload for the operating personnel. Secondly, the finished fabrics achieved a more attractive appearance.

Zongnao Zhou, General Manager of Longgang Deao, states: “We believe that the R 37 is the most advanced semi-automated rotor spinning machine in the world. The fabrics are more even, and efficiency at the weaving mill is higher. Our customers in downstream processing are more satisfied than ever with Deao products.”

Despite its very high rotor speed, the R 37 has a low energy consumption. This is possible thanks to the highly efficient main drives and an efficient suction system. Longgang Deao reported a 10% lower energy consumption of the R 37 compared to the competition.

Easy operation thanks to perfect machine height

Operating personnel not only benefit from the R 37’s high level of productivity, but also from its ergonomic height. This simplifies operator tasks during piecing and doffing. During the AMIspin piecing process, each step is monitored electronically: Once the operating personnel has properly prepared the yarn ends and inserted them into the exit tube, the process starts automatically after the spinning box is closed. This exactly reproducible process forms the basis for consistent piecing quality, which can be monitored with the yarn clearer and leads to noticeably trouble-free downstream processing.

Doffing of entire machine is twice as fast

The ergonomic of operation jointly with the perfect height of the machine also allows a much faster doffing. According to feedback from customers, only around half the time is required to doff the entire machine R 37 in comparison to other similar machines – even when working with large cans. All important components are directly and easily accessible to the operating personnel and are logically arranged from top to bottom. This ensures better monitoring and results in consistently good yarn quality.

The new optional ROBOdoff can automatically replace the full packages with prepared empty tubes without interrupting the spinning process. This simplifies the arduous task of manual doffing. ROBOdoff can use the information when a package is full and ensures that there is a sufficient transfer tail on the new tube.

All of these features make the R 37 the perfect solution for spinning mills that want to benefit from flexibility when selecting raw materials, high productivity, low energy consumption and optimal conditions for operating personnel. The innovative spinning box technology with adaptable trash extraction system ensures competitive yarn quality, even when using cost-effective raw materials.

Textile Excellence

If you wish to Subscribe to Textile Excellence Print Edition, kindly fill in the below form and we shall get back to you with details.