Transparency, Traceability Gains Traction In Fashion Industry

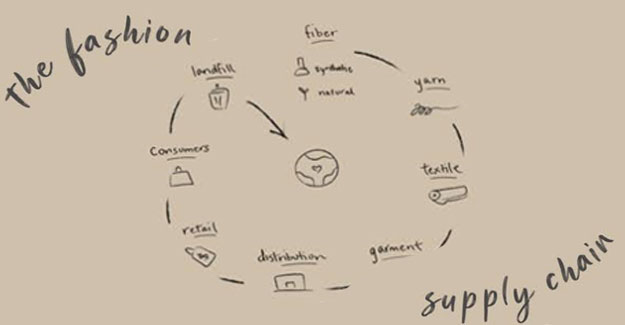

This month has been big for transparency, traceability in the textile industry. Many top retailers and brands are partnering with traceability solution providers to improve transparency in the supply chain, and give credence to their sustainability claims. Hopefully, the momentum will gather pace and continue. Fashion Revolution's annual Fashion Transparency Index has been witnessing a year-on-year increase - 8% in 2017, and 12% in 2019. Traceability is crucial to not only weed out unethical activity; in the long run, traceability also helps clothing recyclers understand what items are made out of so they can reuse or dispose of them properly. Traceability is difficult to achieve and progress is slow. But technology is offering solutions. Here are some of the exciting companies creating tech solutions to transform supply chain traceability. H&M's COS, Next, IBM in blockchain textile traceability project The UK Fashion and Textile Association (UKFT) launched a blockchain traceability project, partnering with IBM and retailers including H&M (COS Brand), Next and New Look. The nine-month sustainability project aims to develop and pilot a supply chain traceability solution for the UK fashion industry and is financially supported by Innovate UK to the tune of GBP 1.4 million (US$ 2 million). The global fashion industry is one of the world's biggest polluters. Data firm Quantis estimates that apparel makes up 6.7% of the world's greenhouse gas emissions, rising to 8% when footwear is included. That's almost four times the estimated emissions from the airline sector. Consumers want to understand the environmental impact of their purchasing behaviour, particularly in an industry that has received widespread criticism over unsafe workplaces, labour abuses and low wages. The issues come down to a lack of transparency. Visibility across different stages of the supply chain is often opaque, and high levels of manual effort mean that parties have little incentive or the means to share data. This means organisations delay implementing more responsible practices and prevents consumers from shopping more sustainably. "Working together, we are pleased to support the development of a new supply chain platform tool for the apparel and textiles sector, to facilitate the gathering of robust sustainability data and provide clear visibility of environmental and ethical impacts to empower better decisions," said Joanne Poynor, Head of Sustainable Development at Next. The new platform will use IBM's blockchain technology to share information about the clothing products - such as place and date of production, product composition and environment-related certificates - accessible to consumers via a QR code. Key supply chain processes will be digitised, creating a shared system of data that different parties can access. This will all be stored on IBM Cloud, which will also use AI technology for optimisation and to detect and respond to supply chain disruption. Other retailers participating in the pilot include N Brown and yarn manufacturer Laxtons. Last year, IBM partnered with German workwear company KAYA&KATO to trace sustainable clothing using blockchain. Meanwhile, this year, the US Cotton Trust Protocol partnered with TextileGenesis to track and trace cotton fibre on its blockchain platform, with leading brands such as Gap and Next using the Trust Protocol. Arvind partners with Textile GenesisTM for blockchain-based track & traceability initiative Arvind Limited too is collaborating with Textile GenesisTM, a blockchain-enabled digital transparency platform, to improve transparency and traceability in its entire denim supply chain. This platform will provide complete traceability of upstream inputs being used by Arvind. This technology works closely with a network of key sustainable fibre suppliers and textile chain partners helping create a sustainable ecosystem for major brands and retailers. "Sustainability and traceability are really two sides of the same coin, and great to see Arvind taking a lead on both fronts. Our supply chain traceability platform will create end-to-end traceability for Arvind's innovative and sustainable products across the entire supply chain using Fibercoins™ traceability technology" said Amit Gautam, CEO & Founder of Textile GenesisTM. Path breaking digital "Fibercoins™" technology from TEXTILE GENESIS™, allows brand and retailers full value chain traceability and visibility along with ESG (environmental, social and governance) credentials of the supply chain partners from fibre origin to retail. Arvind Denim's wide range of sustainable offerings like single-origin non-conflict cotton Renaissance range of recycled cotton, polyester and other man-made fibres; natural indigo etc., will now be available with full track and trace. CIEL Textile partners with Serai to advance supply chain traceability Serai, a digital B2B platform that simplifies global trade, has partnered with leading manufacturer CIEL Textile to map out and trace product-level order flow through their global supply chain. Serai's traceability solution will enable CIEL Textile to access and unify complex supply chain information from multiple sources to gain full visibility over their global supply chain. At the same time, they will be able to collect and analyse important metrics to help them achieve their sustainability goals. This is the first time CIEL Textile has collaborated with a company to gain such in depth supply chain transparency. "CIEL Textile has always been a pioneer in striving for sustainability and innovation. Through Serai's Traceability solution, they will be able to easily collect and manage data from their supply chain partners. Having all this information in one place can help them drive operational efficiencies, manage underlying risks and eventually achieve greater transparency and trust in their extended supply chain," says Vivek Ramachandran, Chief Executive Officer, Serai. A major challenge for CIEL Textile was that they had a diverse range of systems and solutions fragmented across the group. Their garment production comprised a variety of materials including cotton, cellulosic fibres and wool in knitted and woven fabrics which made transparency further upstream difficult. Serai's solution was flexible to adapt to changing requirements and be integrated with CIEL Textile's existing solutions. After evaluating a few technology providers, Serai was chosen based on a criteria comprising the scope of the traceability, flexibility of the solution and integration of global standards to monitor the sustainability performance of CIEL Textile's suppliers. Serai's ambition is to simplify global trade, with an initial focus on the apparel industry. TAF launches digital traceability for Radianza™ fibre Thai Acrylic Fibre Co. Ltd. (TAF) - a part of Aditya Birla Group - has launched a digital traceability platform to trace its flagship fibre brand - Radianza™. This digital platform backed by blockchain technology will ensure complete transparency and traceability for brands, retailers and consumers of Radianza™ fibre in the finished garment. The platform has been developed by Canada based company - Licof Inc. Radianza™ fibre, that uses the revolutionary gel-dyeing technology, has recently become the first and only acrylic fibre to have Material Sustainability Index (MSI) Scores published by Higg Co. based on the Life Cycle Assessment Impact study conducted by Thinkstep (now Sphera). Earlier this year, the TAF become the first and only acrylic fibre company to become a bluesign® SYSTEM partner. Highlighting the effectiveness of blockchain in textile tracing, Ritesh Khare, founder of Licof adds, "Blockchain is a very powerful technology, especially for those at the end of the value chain like brands and retailers to validate the authenticity of the materials they are sourcing in a complex value chain like textile and apparel. Blockchain makes digital tracing and tracking immutable, while a user-friendly platform makes it very easy for the value chain players to collaborate and share relevant information. We are very excited to collaborate with TAF and support them and their customers trace Radianza™ and other specialty fibres."

Textile Excellence

If you wish to Subscribe to Textile Excellence Print Edition, kindly fill in the below form and we shall get back to you with details.