Rieter: How To Boost Profitability And Performance With Tailored Mill Solutions

Spinning mill owners face ever new challenges in today’s uncertain environment. Rieter’s Performance Optimization Services (POS) developed a tailored mill solution for a customer in India that helped reduce energy consumption by 3 kWh/h per compact-spinning machine while improving productivity by up to 10%. At the same time, yarn realization was increased by up to 1%. This highlights how targeted optimisations can add up to a big impact.

The owner of a Rieter compact-spinning system in India was faced with a difficult choice – either improve his mill or lose out to competitors with newer spinning mills. His machines were about 15 years old and while they were well maintained, it was clear that the mill needed improvements across the board, from lowering energy costs through to increasing productivity and yarn quality. He turned to Rieter to understand the options at his disposal.

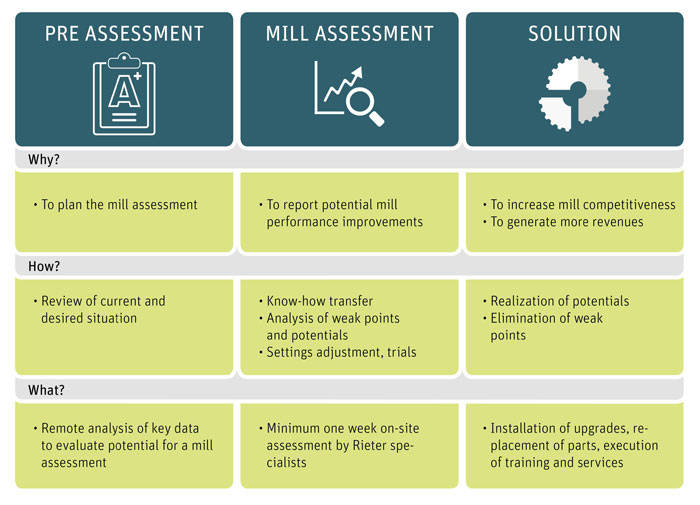

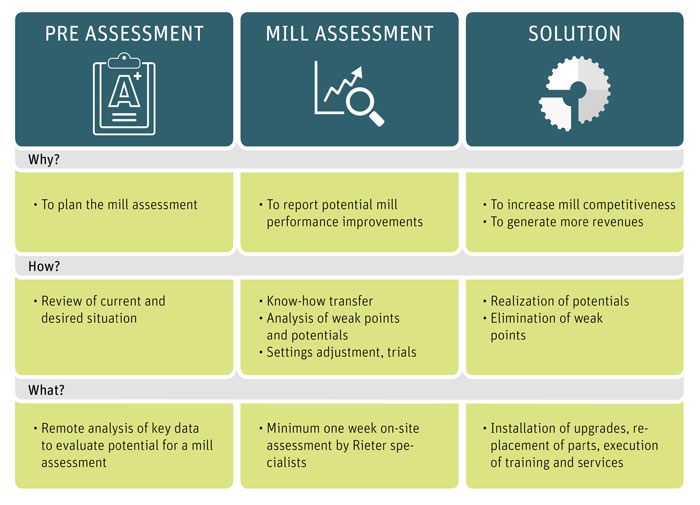

This is where Rieter brought in its POS which aim to maintain the competitiveness of spinning mills in terms of productivity, conversion cost and yarn quality over the lifetime of the machines. This requires compensation for technical wear and tear as well as ensuring that the gap between the existing mill’s performance and that of new spinning mills is kept as low as possible. To realise this target in an economical way, the POS approach focuses on maximising customer’s return on investment. This is achieved by optimising the whole spinning process from bale to yarn rather than just looking at single process steps. “Rieter’s POS service concept leverages our vast experience across the whole spinning process,” explains Ashutosh Chamola, Vice President India, Business Group After Sales. “The concept is tailored to meet individual customer needs and follows a three-step optimisation approach: 1. Pre Assessment, 2. Mill Assessment, and 3. Solution.” (Fig. 1)

[caption id="attachment_22541" align="alignnone" width="700"] The three-step approach of Rieter’s POS helps to capture market opportunities. (Fig 1)[/caption]

In the first step, the pre-assessment, the POS-team, which is entirely made up of yarn technology experts, records the customer’s desired improvements and creates an overview of the current situation through remote analysis. The Rieter machines installed at the site are reviewed and the customer’s areas of concern are discussed. Through these measures, the pre-assessment defines the goals and focus areas for the next steps. For the customer in question, the request was to provide a comprehensive solution to support long-term competitiveness of the spinning mill in terms of energy cost, productivity and yarn quality.

In the second step, the mill assessment, Rieter experts from the field service and textile technology departments visit the spinning mill. The team assesses the current performance of the spinning mill, conducts trials and provides advice on adjusting machine settings on the spot. The aim is to optimise the entire Rieter spinning process aligned to customer requirements so that customers can realise the system’s full performance potential. During this period a constant exchange between the Rieter team and the customer is crucial. (Fig. 2). In this case, the POS-team conducted a thorough analysis of the entire spinning mill and optimised various machine settings. Rieter’s POS team made it a priority to understand the root causes that were affecting the current performance level of the mill.

Based on the findings, Rieter’s POS team recommended a series of measures which included the installation of upgrade packages. Drawing from the company’s broad after-sales portfolio, the team recommended the installation of the suction tubes ECOrized to the compact-spinning machines to reduce energy consumption.

The third step of the POS concept is the Solution, which is tailored to meet the customer’s needs precisely and improve the performance of the mill. The combination of measures is based on the desired improvements defined during pre assessment as well as the findings during the mill assessment. In addition to replacing machine parts and installing upgrades as was the case for this customer, the solution can sometimes extend to staff training and providing textile technology services.

For this customer, the recommendations included measures that resulted in a reduction in energy consumption on each of the compact spinning machines by 3 kWh per hour. Furthermore, productivity was increased by up to 10% and yarn realisation was improved by up to 1% across different yarn counts while improving yarn quality. The customer’s expectations have been exceeded, and he is now fully prepared to face the competition.

The three-step approach of Rieter’s POS helps to capture market opportunities. (Fig 1)[/caption]

In the first step, the pre-assessment, the POS-team, which is entirely made up of yarn technology experts, records the customer’s desired improvements and creates an overview of the current situation through remote analysis. The Rieter machines installed at the site are reviewed and the customer’s areas of concern are discussed. Through these measures, the pre-assessment defines the goals and focus areas for the next steps. For the customer in question, the request was to provide a comprehensive solution to support long-term competitiveness of the spinning mill in terms of energy cost, productivity and yarn quality.

In the second step, the mill assessment, Rieter experts from the field service and textile technology departments visit the spinning mill. The team assesses the current performance of the spinning mill, conducts trials and provides advice on adjusting machine settings on the spot. The aim is to optimise the entire Rieter spinning process aligned to customer requirements so that customers can realise the system’s full performance potential. During this period a constant exchange between the Rieter team and the customer is crucial. (Fig. 2). In this case, the POS-team conducted a thorough analysis of the entire spinning mill and optimised various machine settings. Rieter’s POS team made it a priority to understand the root causes that were affecting the current performance level of the mill.

Based on the findings, Rieter’s POS team recommended a series of measures which included the installation of upgrade packages. Drawing from the company’s broad after-sales portfolio, the team recommended the installation of the suction tubes ECOrized to the compact-spinning machines to reduce energy consumption.

The third step of the POS concept is the Solution, which is tailored to meet the customer’s needs precisely and improve the performance of the mill. The combination of measures is based on the desired improvements defined during pre assessment as well as the findings during the mill assessment. In addition to replacing machine parts and installing upgrades as was the case for this customer, the solution can sometimes extend to staff training and providing textile technology services.

For this customer, the recommendations included measures that resulted in a reduction in energy consumption on each of the compact spinning machines by 3 kWh per hour. Furthermore, productivity was increased by up to 10% and yarn realisation was improved by up to 1% across different yarn counts while improving yarn quality. The customer’s expectations have been exceeded, and he is now fully prepared to face the competition.

Textile Excellence

If you wish to Subscribe to Textile Excellence Print Edition, kindly fill in the below form and we shall get back to you with details.