Automatic Dosing Systems : Fast, Accurate And Eco-Friendly

Established in 1987, Color Service is an Italian leading company in the development and production of automatic dosing systems of powder and liquid products.

The technology is developed to solve problems associated with the manual weighing of products and it is designed with the aim to abandon traditional and outdated production methods that inevitably would not allow to get a safe, fast and precise dosing.

Dyeing right the first time is a mandatory condition to hold down costs, meet customer deliveries, to avoid uncontrolled weighing mistakes, and to avoid waste of products (both for chemicals, auxiliaries and for powder dyes). The different production phases needed to have the finished fabric or garment had to be monitored in order to retrace the origin of the eventual defect.

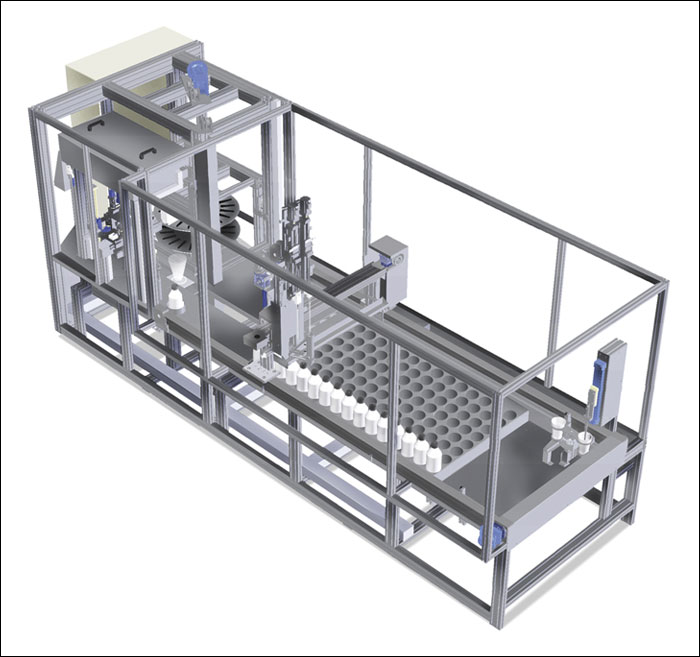

Color Service offers solutions for both production and laboratory, from automatic dosing and dissolving system for dyestuffs, liquids, auxiliaries and powder chemicalsfor dyeing and printing houses.

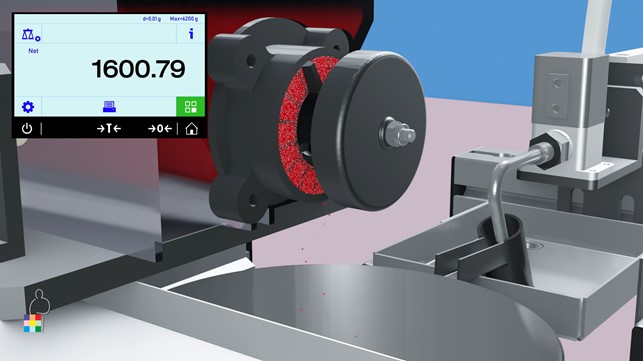

The company is the first to introduce into the market the first automatic dosing systems for dyestuffs, changing the approach of textile market towards the automation. Its weighing unit mod. TRS automatically weighs any type of dyestuff in powder or in granule form through high speed irrigation screws and with a special scraper a remarkable accuracy within small weighing can be achieved. This unit is combined with the wide range of automatic dissolving systems, which dissolve the dosed recipe and transfer it to the customer's destinations based on the dissolution parameters and the amount to feed dyeing machines.

Color Service offers solutions for both production and laboratory, from automatic dosing and dissolving system for dyestuffs, liquids, auxiliaries and powder chemicalsfor dyeing and printing houses.

The company is the first to introduce into the market the first automatic dosing systems for dyestuffs, changing the approach of textile market towards the automation. Its weighing unit mod. TRS automatically weighs any type of dyestuff in powder or in granule form through high speed irrigation screws and with a special scraper a remarkable accuracy within small weighing can be achieved. This unit is combined with the wide range of automatic dissolving systems, which dissolve the dosed recipe and transfer it to the customer's destinations based on the dissolution parameters and the amount to feed dyeing machines.

In addition to this, Color Service produces gravimetric/volumetric automatic dosing system for liquid chemicals and auxiliaries, merging the speed of volumetric measurement with the precision of gravimetric dosing, as well as dosing/dissolving units for powder chemicals (Salt, Soda, Sodium), preparing the solution without alteration of the correct liquor ratio.

In the textile sector, the laboratory dyeing is fundamental to simulate the real dyeing production process. A wide range of laboratory equipment is designed and provided by Color Service such as automatic dyeing batches and solutions maker, volumetric solutions dosing system with pipetting, automatic dye and chemical dispenser for small machines.

All Color Service dispensing systems are able to guarantee a high accuracy of the dosing, reproducibility of the recipes, high production speed that makes the production process repetitive 24/7 and reliable, allowing a “zero defects” production. Thus limiting the human intervention and reducing to zero the risk factors. All processes of the systems are traceable as well as automatically monitored and data are recorded in the software developed to be user friendly and intuitive.

All Color Service production is entirely made in Italy on three premises (total production area 15.000 sqm, with 160 people working), a unique feature that is synonymous with cutting-edge systems and high technology.

The solutions offered by Color Service are the result of continuous researches and studies, especially oriented to the environmental sustainability. For this reason, Color Service has invested heavily in research and development and is now able to guarantee a completely closed and aspirated system with absolute control of the dust emitted during the weighing and the suction of the product that are recovered and reintroduced into the production cycle with obvious ecological and economic benefits.

In addition to this, Color Service produces gravimetric/volumetric automatic dosing system for liquid chemicals and auxiliaries, merging the speed of volumetric measurement with the precision of gravimetric dosing, as well as dosing/dissolving units for powder chemicals (Salt, Soda, Sodium), preparing the solution without alteration of the correct liquor ratio.

In the textile sector, the laboratory dyeing is fundamental to simulate the real dyeing production process. A wide range of laboratory equipment is designed and provided by Color Service such as automatic dyeing batches and solutions maker, volumetric solutions dosing system with pipetting, automatic dye and chemical dispenser for small machines.

All Color Service dispensing systems are able to guarantee a high accuracy of the dosing, reproducibility of the recipes, high production speed that makes the production process repetitive 24/7 and reliable, allowing a “zero defects” production. Thus limiting the human intervention and reducing to zero the risk factors. All processes of the systems are traceable as well as automatically monitored and data are recorded in the software developed to be user friendly and intuitive.

All Color Service production is entirely made in Italy on three premises (total production area 15.000 sqm, with 160 people working), a unique feature that is synonymous with cutting-edge systems and high technology.

The solutions offered by Color Service are the result of continuous researches and studies, especially oriented to the environmental sustainability. For this reason, Color Service has invested heavily in research and development and is now able to guarantee a completely closed and aspirated system with absolute control of the dust emitted during the weighing and the suction of the product that are recovered and reintroduced into the production cycle with obvious ecological and economic benefits.

“Indeed, one of the cardinal goal of our technology is to drastically reduce environmental and ecological risks with the restraint of energy/water consumption, the reduction of environmental pollution and material wasting in order to create a sustainable finished product for customers,” says the company.

With 35 years of activity, Color Service obtained rewarding results such as widespread commercial net, constant technical assistance through remote or onsite support and a large clientele that includes the most renowned textile companies in the world.

“Thanks to our system’s automation, we guarantee our customers more production in less time, more coordination, reduction of the margins of error in all the processing phases, more energy saving, less wastes, more company profits and more safety for the operators.”

“Indeed, one of the cardinal goal of our technology is to drastically reduce environmental and ecological risks with the restraint of energy/water consumption, the reduction of environmental pollution and material wasting in order to create a sustainable finished product for customers,” says the company.

With 35 years of activity, Color Service obtained rewarding results such as widespread commercial net, constant technical assistance through remote or onsite support and a large clientele that includes the most renowned textile companies in the world.

“Thanks to our system’s automation, we guarantee our customers more production in less time, more coordination, reduction of the margins of error in all the processing phases, more energy saving, less wastes, more company profits and more safety for the operators.”

Textile Excellence

If you wish to Subscribe to Textile Excellence Print Edition, kindly fill in the below form and we shall get back to you with details.