Rieter: Processing Colored Recycled Fibres On The R 37

With the semi-automated rotor spinning machine R 37 the Cangnan Zijian cotton mill produces coloured yarn from a blend of recycled cotton and polyester. Downstream customers appreciate the high yarn quality and the sustainable production.

Cangnan Zijian Cotton Co., Ltd. is located in Cangnan County, Zhejiang Province, China, and is specialized in the production of recycled woven denim yarns Ne 7 and Ne 10, which are mainly sold in domestic markets. Zijian uses a blend of recycled cotton and polyester as raw material. They categorize waste cloth according to color, open it up to single fibres and blend it with polyester. This blend is directly processed into colored yarn (Fig. 1). With the Rieter semi-automated rotor spinning machine R 37, Cangnan Zijian profits from efficient yarn production and meets the weaving requirements of downstream customers.

[caption id="attachment_23685" align="alignnone" width="700"] Mr. Shanghao Li, General Manager, is pleased with the high delivery speed of the R 37. (Fig. 2)[/caption]

The demands on yarn quality are increasing

Weaving mills and downstream customers place high demands on the fabric surface. If the yarn quality is insufficient for weaving mills due to yarn breaks and imperfections, spinning mills may face financial penalties. As a constantly developing small spinning mill, Cangnan Zijian needs to maintain recognition among customers. Therefore, it needs spinning machines with high performance and stable running behavior that deliver good yarn quality.

High flexibility also for smaller lots

The semi-automated rotor spinning machine R 37 is the right choice for colored recycled fibres. Cangnan Zijian profits from maximum flexibility also for smaller lots with different colors. Independent machine sides open up the possibility to spin different lots on each side. Thanks to the new spinning box, the extraction of trash and short fibres becomes more selective, which is especially helpful when processing recycled fibres. The loss of good fibres is reduced. The yarn quality meets customers’ high expectations, offering good tenacity and low imperfections for great weaving results. Low energy consumption and easy, time-saving handling by operating personnel minimize production costs.

Lower environmental impact

Due to its high quality, downstream customers prefer the yarn produced on the R 37 to that produced on the competitor's machine. As the recycled fibres are already colored the yarn no longer needs to be dyed in the downstream processes. This makes the production more sustainable as water pollution and the use of chemicals are reduced. An important fact that makes the yarn even more popular with yarn traders and weavers.

[caption id="attachment_23686" align="alignnone" width="700"]

Mr. Shanghao Li, General Manager, is pleased with the high delivery speed of the R 37. (Fig. 2)[/caption]

The demands on yarn quality are increasing

Weaving mills and downstream customers place high demands on the fabric surface. If the yarn quality is insufficient for weaving mills due to yarn breaks and imperfections, spinning mills may face financial penalties. As a constantly developing small spinning mill, Cangnan Zijian needs to maintain recognition among customers. Therefore, it needs spinning machines with high performance and stable running behavior that deliver good yarn quality.

High flexibility also for smaller lots

The semi-automated rotor spinning machine R 37 is the right choice for colored recycled fibres. Cangnan Zijian profits from maximum flexibility also for smaller lots with different colors. Independent machine sides open up the possibility to spin different lots on each side. Thanks to the new spinning box, the extraction of trash and short fibres becomes more selective, which is especially helpful when processing recycled fibres. The loss of good fibres is reduced. The yarn quality meets customers’ high expectations, offering good tenacity and low imperfections for great weaving results. Low energy consumption and easy, time-saving handling by operating personnel minimize production costs.

Lower environmental impact

Due to its high quality, downstream customers prefer the yarn produced on the R 37 to that produced on the competitor's machine. As the recycled fibres are already colored the yarn no longer needs to be dyed in the downstream processes. This makes the production more sustainable as water pollution and the use of chemicals are reduced. An important fact that makes the yarn even more popular with yarn traders and weavers.

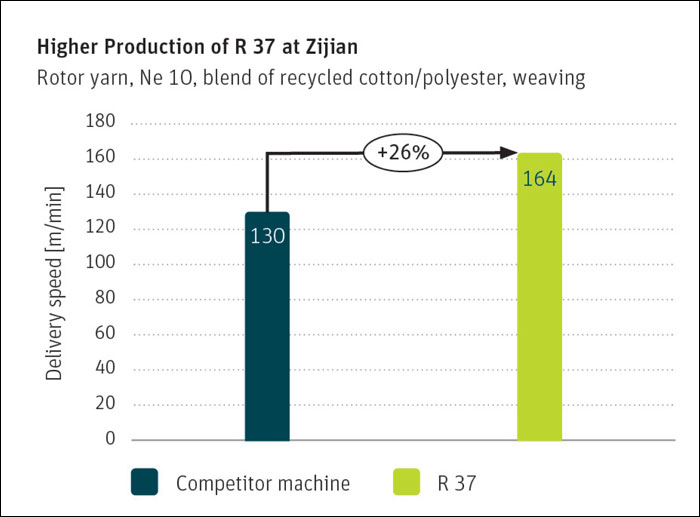

[caption id="attachment_23686" align="alignnone" width="700"] The R 37 has 26% higher production than the competitor machine.[/caption]

26% higher delivery speed

“The rotor spinning machine R 37 is characterized by high delivery speed, good equipment, high-quality components, high processing accuracy and easy operation. Especially when spinning coarse yarn, the delivery speed of the R 37 is very attractive”, states Mr. Shanghao Li, General Manager of Cangnan Zijian (Fig. 2). It produces at a 26% higher delivery speed than the competitor machine (Fig. 3). Energy consumption per ton of yarn has been reduced at Cangnan Zijian thanks to highly efficient main drives and its energy-saving design concept. The simplified design of the R 37 helps to save costs related to replacing components after extended operation. When abrasive raw material results in high wear and tear, the fibre channel can be exchanged easily. Also, the trash channel can be replaced without using tools to adapt the trash extraction to the raw material.

The R 37 has 26% higher production than the competitor machine.[/caption]

26% higher delivery speed

“The rotor spinning machine R 37 is characterized by high delivery speed, good equipment, high-quality components, high processing accuracy and easy operation. Especially when spinning coarse yarn, the delivery speed of the R 37 is very attractive”, states Mr. Shanghao Li, General Manager of Cangnan Zijian (Fig. 2). It produces at a 26% higher delivery speed than the competitor machine (Fig. 3). Energy consumption per ton of yarn has been reduced at Cangnan Zijian thanks to highly efficient main drives and its energy-saving design concept. The simplified design of the R 37 helps to save costs related to replacing components after extended operation. When abrasive raw material results in high wear and tear, the fibre channel can be exchanged easily. Also, the trash channel can be replaced without using tools to adapt the trash extraction to the raw material.

Textile Excellence

If you wish to Subscribe to Textile Excellence Print Edition, kindly fill in the below form and we shall get back to you with details.