LMW’s Lap Former LH20 S Raised Productivity By 30% At Birin Spinning Mills

Birin Spinning Mills Limited is a leading modern mill manufacturing cotton yarn, strategically located in Avinashi, from where both the textile hubs of Coimbatore and Tirupur can be easily accessed.

The company, with a strong technology focus has grown multifold over the years and has been catering to the needs of clients both in the domestic and key overseas markets such as Japan and Vietnam.

[caption id="attachment_23773" align="alignnone" width="700"] LMW's Lap Former LH20 S model.[/caption]

Birin Spinning Mills started its operation in 2002 with 4,800 spindles and gradually increased its capacity to 16,800 spindles by 2019. Mr. Muthu Venkatesh came onboard as the Technical Director after completion of his engineering degree. According to him, the success of their long standing dominance in the market is due to modernisation of machines and incorporation of latest technology in their work place.

Birin Spinning Mills was producing 40’s Ne combed compact hosiery with yarn production capacity of 8400 kgs per day. Once they targeted to increase yarn productivity, the two existing Lap Formers became the bottleneck as it was only producing 9550 kgs per day against the requirement of 10,500 kgs per day. Additionally, a considerable bandwidth of their available workforce was engaged in the maintenance of the old machinery as well.

The company decided to replace the existing 2 nos. Lap Former with single Lap Former LH20 S model, after meticulously evaluating the benefits offered by it, which gave them an impressive output of 12,500 kgs per day at 190 mpm at an increased efficiency rate of 72%. The Lap Former LH20 S productivity has increased up to 30% after the modernisation.

[caption id="attachment_23771" align="alignnone" width="700"]

LMW's Lap Former LH20 S model.[/caption]

Birin Spinning Mills started its operation in 2002 with 4,800 spindles and gradually increased its capacity to 16,800 spindles by 2019. Mr. Muthu Venkatesh came onboard as the Technical Director after completion of his engineering degree. According to him, the success of their long standing dominance in the market is due to modernisation of machines and incorporation of latest technology in their work place.

Birin Spinning Mills was producing 40’s Ne combed compact hosiery with yarn production capacity of 8400 kgs per day. Once they targeted to increase yarn productivity, the two existing Lap Formers became the bottleneck as it was only producing 9550 kgs per day against the requirement of 10,500 kgs per day. Additionally, a considerable bandwidth of their available workforce was engaged in the maintenance of the old machinery as well.

The company decided to replace the existing 2 nos. Lap Former with single Lap Former LH20 S model, after meticulously evaluating the benefits offered by it, which gave them an impressive output of 12,500 kgs per day at 190 mpm at an increased efficiency rate of 72%. The Lap Former LH20 S productivity has increased up to 30% after the modernisation.

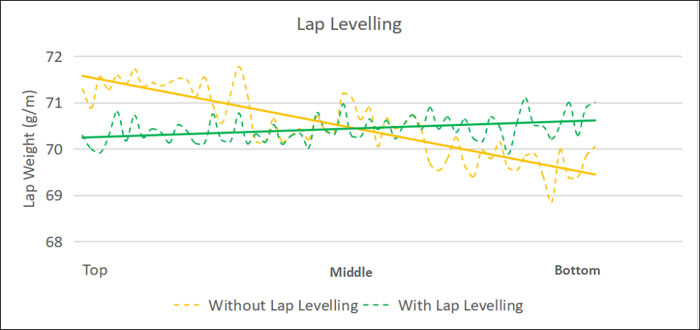

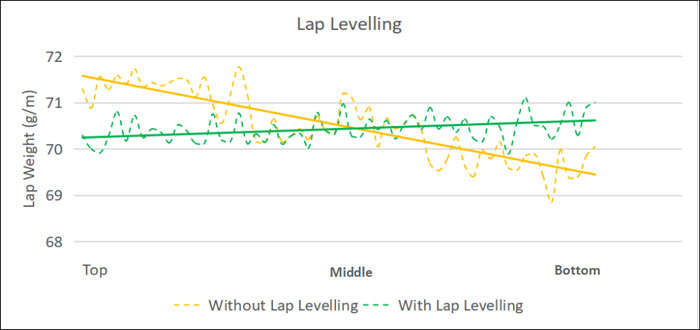

[caption id="attachment_23771" align="alignnone" width="700"] Graph showing consistent lap weight through servo draft lap levelling[/caption]

The LH20 S possesses an in-built Lap Weight Monitoring System, along with Servo Drive Drafting System, that enables it to automatically adjust the draft to maintain defined lap weight. The unique concept of single-head drafting implemented by LMW helps in achieving best-in-class lap appearance, and avoids associated maintenance problems. The machine operates at fastest recorded doff-time, resulting in increased machine efficiency.

The following are the advantages of Servo draft coupled with Lap Weight Monitoring system:

Graph showing consistent lap weight through servo draft lap levelling[/caption]

The LH20 S possesses an in-built Lap Weight Monitoring System, along with Servo Drive Drafting System, that enables it to automatically adjust the draft to maintain defined lap weight. The unique concept of single-head drafting implemented by LMW helps in achieving best-in-class lap appearance, and avoids associated maintenance problems. The machine operates at fastest recorded doff-time, resulting in increased machine efficiency.

The following are the advantages of Servo draft coupled with Lap Weight Monitoring system:

- Manual checking of lap weight is eliminated

- Consistent and lesser Lap CV%

- Noil consistency in comber

- Even exhaust of laps in comber benefits soft waste saving of upto 0.5% results in additional yarn production of approx. 16 T per year

- Saving in soft waste process cost

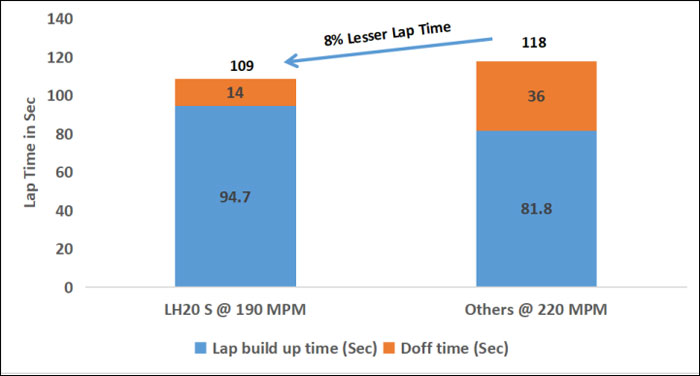

Graph showing lesser lap time resulting in increased machine efficiency.[/caption]

Lesser doff time for increased productivity

With the unique design of calendering, lap built and lap change system Lap Former LH20 S is able to achieve the fastest doff time, resulting in highest machine efficiency of up to 72%, which still remains as the benchmark in the industry.

Lesser maintenance

Lap Former LH20 S has in-built user friendly features that results in lesser maintenance and provides a greater advantage on the recurring and ownership cost.

Graph showing lesser lap time resulting in increased machine efficiency.[/caption]

Lesser doff time for increased productivity

With the unique design of calendering, lap built and lap change system Lap Former LH20 S is able to achieve the fastest doff time, resulting in highest machine efficiency of up to 72%, which still remains as the benchmark in the industry.

Lesser maintenance

Lap Former LH20 S has in-built user friendly features that results in lesser maintenance and provides a greater advantage on the recurring and ownership cost.

Textile Excellence

If you wish to Subscribe to Textile Excellence Print Edition, kindly fill in the below form and we shall get back to you with details.