Zilingo - Your Gateway To Industry 4.0

Industry 4.0 raises the bar on what digital technology can offer by allowing access to real-time data, and introducing interconnectivity between product and people through the Internet, artificial intelligence and machine learning. The nine technologies said to be transforming industrial production are:

- Big data and analytics

- The Industrial Internet of Things

- Horizontal and vertical system integration

- Cloud computing

- Additive manufacturing

- Augmented reality

- Autonomous robots

- Simulation

- Cybersecurity

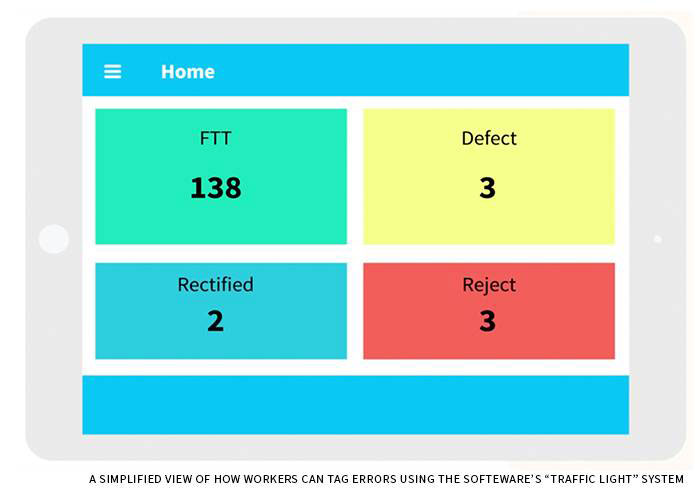

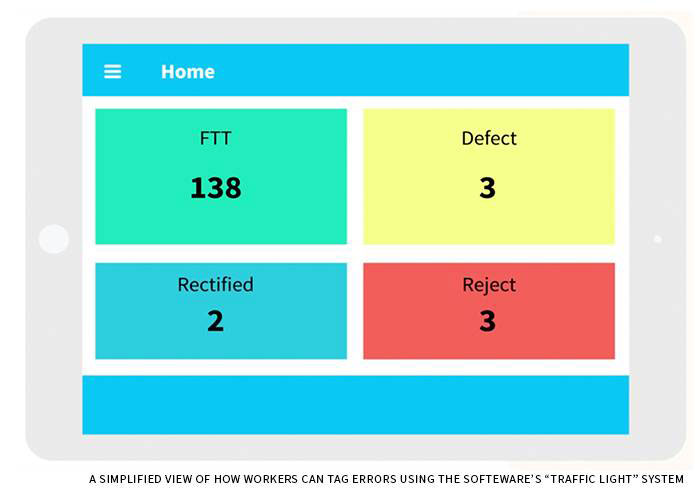

A simplified view of how workers can tag errors using the software’s `Traffic Light’ System.[/caption]

For the fashion industry, big data and analytics, and the Industrial Internet of Things, are more relevant.

Why do I need big data?

Factory production data arrives from multiple sources, in staggering volumes, and at different timings. These variables make it nearly impossible to evaluate the quality of such data, much less generate insights from them. With the push towards big data in Industry 4.0, however, numbers are streamlined, tallied and made available without delay.

The real objective of big data and analytics, is harnessing them in the right way quickly to support strategic decision-making.

The Industrial Internet of what?

Yes, the Industrial Internet of Things. We know that computers and the internet aren’t new, so it’s easy to forget that these industry-shaping technologies are still advancing at a pace that outruns previous decades.

Today, computers have the capacity to think beyond what they’ve been programmed to do, and are communicating between themselves in hyper-connected systems without human involvement. We call this artificial intelligence (AI) and machine learning.

By becoming smarter and more autonomous through a constant stream of big data mentioned earlier, computers can share this information with manufacturing owners instantaneously through the cloud. Owners and stakeholders are then enabled to make strategic and executional business decisions that are based on logic rather than emotions.

Together, big data and the Industrial Internet of Things bring about what’s known as smart factories – large scale facilities that are truly efficient and productive.

[caption id="attachment_23914" align="alignleft" width="700"]

A simplified view of how workers can tag errors using the software’s `Traffic Light’ System.[/caption]

For the fashion industry, big data and analytics, and the Industrial Internet of Things, are more relevant.

Why do I need big data?

Factory production data arrives from multiple sources, in staggering volumes, and at different timings. These variables make it nearly impossible to evaluate the quality of such data, much less generate insights from them. With the push towards big data in Industry 4.0, however, numbers are streamlined, tallied and made available without delay.

The real objective of big data and analytics, is harnessing them in the right way quickly to support strategic decision-making.

The Industrial Internet of what?

Yes, the Industrial Internet of Things. We know that computers and the internet aren’t new, so it’s easy to forget that these industry-shaping technologies are still advancing at a pace that outruns previous decades.

Today, computers have the capacity to think beyond what they’ve been programmed to do, and are communicating between themselves in hyper-connected systems without human involvement. We call this artificial intelligence (AI) and machine learning.

By becoming smarter and more autonomous through a constant stream of big data mentioned earlier, computers can share this information with manufacturing owners instantaneously through the cloud. Owners and stakeholders are then enabled to make strategic and executional business decisions that are based on logic rather than emotions.

Together, big data and the Industrial Internet of Things bring about what’s known as smart factories – large scale facilities that are truly efficient and productive.

[caption id="attachment_23914" align="alignleft" width="700"] A simplified view of how workers can tag errors using the software’s `Traffic Light’ System.[/caption]

Is software really the solution?

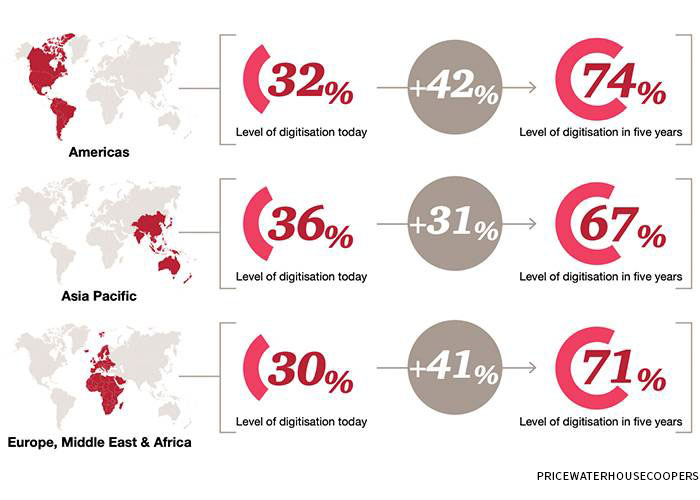

Definitely. A 2016 Global Industry 4.0 Survey by PriceWaterhouseCoopers predicted a significant increase of digitalisation across regions in the next five years, with Asia Pacific noted to have considerable push towards Industry 4.0. For manufacturers that want to see the largest gains, digitisation is and will always be a priority, not an option.

Zilingo Factory Software

Zilingo Factory Software is a powerful yet user-friendly enterprise-management system that will take fashion businesses out of a state of flux and into the future. This enterprise resource planning software unlocks access to real-time production data by empowering workers, managers and factory owners in the production process.

Here’s how it works: First, workers input product defects data into tablets conveniently located on the factory floor next to the production line. The software interface uses accessible colour-coded buttons that make tagging a cinch. As the number of products that have passed or failed quality checks increase, the software aggregates production output to form big data.

[caption id="attachment_23915" align="alignleft" width="700"]

A simplified view of how workers can tag errors using the software’s `Traffic Light’ System.[/caption]

Is software really the solution?

Definitely. A 2016 Global Industry 4.0 Survey by PriceWaterhouseCoopers predicted a significant increase of digitalisation across regions in the next five years, with Asia Pacific noted to have considerable push towards Industry 4.0. For manufacturers that want to see the largest gains, digitisation is and will always be a priority, not an option.

Zilingo Factory Software

Zilingo Factory Software is a powerful yet user-friendly enterprise-management system that will take fashion businesses out of a state of flux and into the future. This enterprise resource planning software unlocks access to real-time production data by empowering workers, managers and factory owners in the production process.

Here’s how it works: First, workers input product defects data into tablets conveniently located on the factory floor next to the production line. The software interface uses accessible colour-coded buttons that make tagging a cinch. As the number of products that have passed or failed quality checks increase, the software aggregates production output to form big data.

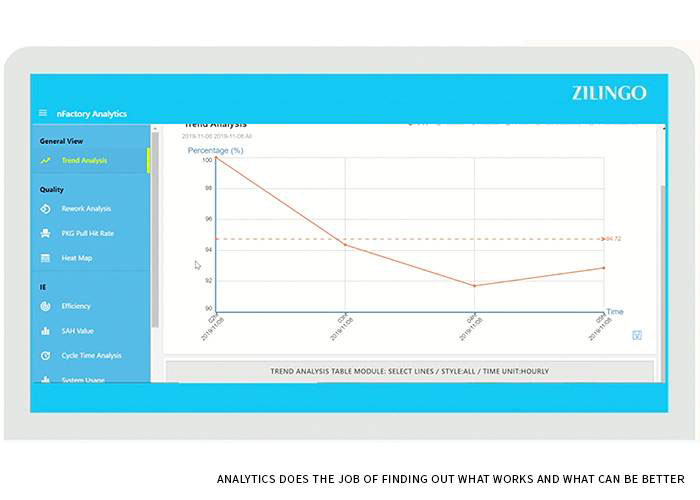

[caption id="attachment_23915" align="alignleft" width="700"] Analytics does the job of finding out what works and what can be better.[/caption]

This chunk of data is summarised, analysed and displayed on a central dashboard on the production line alongside key indicators such as production targets, current progress and operating efficiency. Key personnel can view this summary and make adjustments to improve production flow instantly.

An analytics app then tracks this data over a period of time and automatically generates reports, putting to rest the days of tedious spreadsheet work behind a desk. These reports, directly accessible on any device thanks to cloud computing, produce actionable insights for upper management to make high-level decisions without having to be physically present at the manufacturing facility.

That’s the magic of Industry 4.0 — the ability to track performance, stay ahead of the curve and rely on digital capabilities to deliver insights at speed allows human resources to focus on business and sales strategy, optimisation and expansion with minimum margin of error. Zilingo Factory Software is designed to be scalable, easy-to-use and mobile-friendly, with manufacturers seeing efficiency improvements in just weeks. Production outputs rise by up to 12%, while defects see a drop of up to 50%, according to Zilingo team.

Analytics does the job of finding out what works and what can be better.[/caption]

This chunk of data is summarised, analysed and displayed on a central dashboard on the production line alongside key indicators such as production targets, current progress and operating efficiency. Key personnel can view this summary and make adjustments to improve production flow instantly.

An analytics app then tracks this data over a period of time and automatically generates reports, putting to rest the days of tedious spreadsheet work behind a desk. These reports, directly accessible on any device thanks to cloud computing, produce actionable insights for upper management to make high-level decisions without having to be physically present at the manufacturing facility.

That’s the magic of Industry 4.0 — the ability to track performance, stay ahead of the curve and rely on digital capabilities to deliver insights at speed allows human resources to focus on business and sales strategy, optimisation and expansion with minimum margin of error. Zilingo Factory Software is designed to be scalable, easy-to-use and mobile-friendly, with manufacturers seeing efficiency improvements in just weeks. Production outputs rise by up to 12%, while defects see a drop of up to 50%, according to Zilingo team.

Textile Excellence

Subscribe To Textile Excellence Print Edition

If you wish to Subscribe to Textile Excellence Print Edition, kindly fill in the below form and we shall get back to you with details.