LMW Showcases Its Latest Innovations At ITM, 2022

Lakshmi Machine Works Limited (LMW) is showcasing its latest innovations at International Textile Machinery Exhibition, ITM 2022, in Istanbul, Turkey from 14-18 June, 2022. ITM Turkey is an important trade fair in the region, for textile machinery and solution providers to exhibit the latest offerings in their portfolio. LMW is showcasing the following solutions :

- Latest carding solution (Card LC636S)

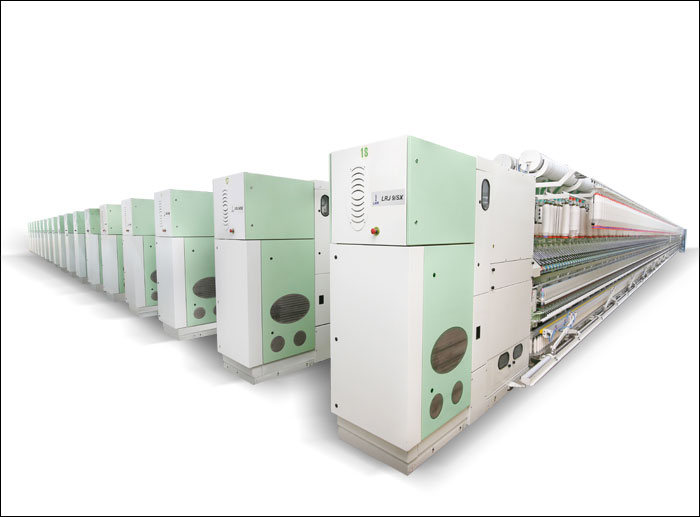

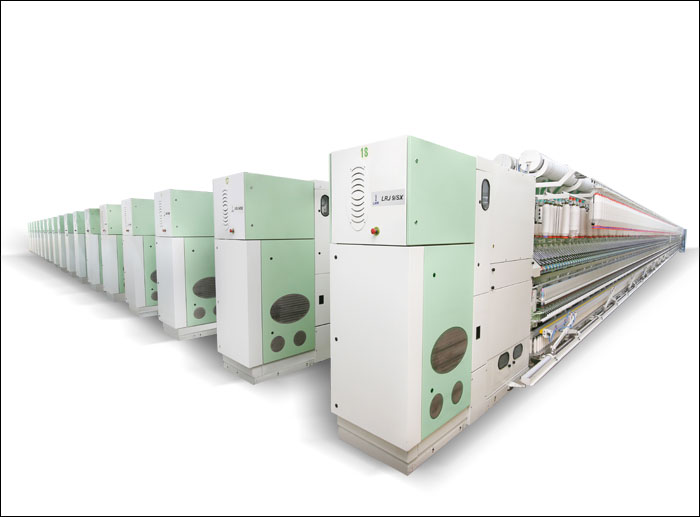

- Futuristic ring spinning solution (Ring FrameLRJ9/SX)

Smart RF[/caption]

Automation focused on reducing dependence on skilled manpower

LMW is constantly working to reduce dependence on skilled manpower by introducing innovative solutions with the right balance of automation and ergonomics. Some of its widely accepted offerings include :

Smart RF[/caption]

Automation focused on reducing dependence on skilled manpower

LMW is constantly working to reduce dependence on skilled manpower by introducing innovative solutions with the right balance of automation and ergonomics. Some of its widely accepted offerings include :

- Auto blend LA 10 in Blowroom for automatic blending of various material

- Automatic Lap Transportation System (LTS)

- Auto doffer Speedframe

- Roving Transportation System (RTS)

- Ring Frame Auto Piecing (RAP)

- Spin Connect

Textile Excellence

Subscribe To Textile Excellence Print Edition

If you wish to Subscribe to Textile Excellence Print Edition, kindly fill in the below form and we shall get back to you with details.