New Report Stresses Urgent Need For Textile Circularity

The Eileen Fisher Foundation commissioned a report to support the apparel industry to confront the climate crisis. Authored by Pentatonic, it focuses on the issue of textile waste and how circularity can be leveraged to effectively address it.

It is no longer a question of if the industry will adopt circular strategies but how. The latest IPCC Report, the starkest yet, warns that without immediate and deep emissions reductions across all sectors in the next three years, limiting global warming to 1.5°C is beyond reach.

The quantity of clothing entering the market has expanded rapidly over the last decade with 150 billion new clothing items produced annually. Currently, the volume of clothing produced and discarded is growing at a faster rate than recycling facilities can process.

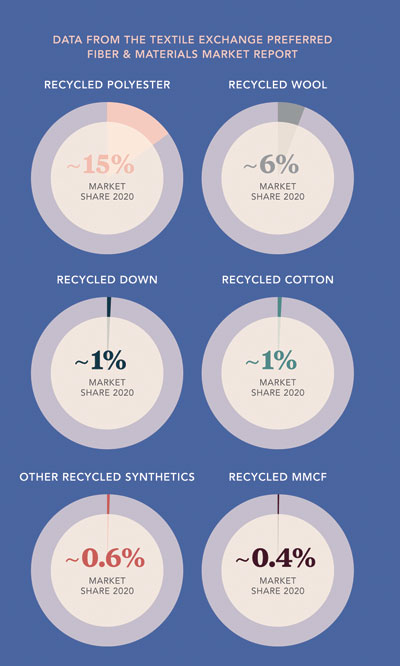

In addition, highly recyclable or compostable materials only represent a nominal share of the overall market. Textile waste is a global issue, with the negative environmental and socio-economic consequences of overproduction and consumption already widespread.

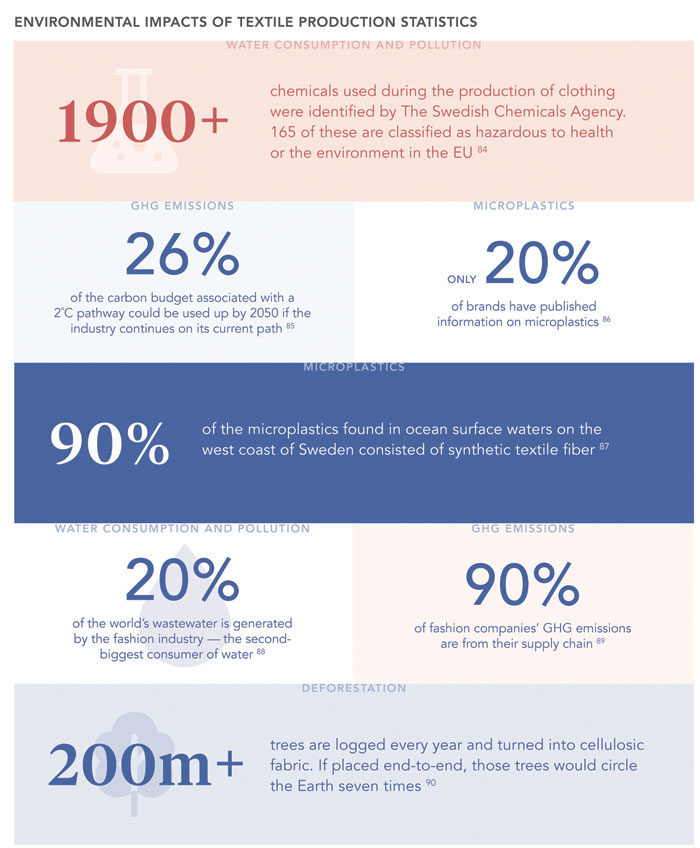

Beyond textile waste, the industry is also struggling to keep its emissions in check. Notably, the fashion industry is the third highest producer of greenhouse gas emissions globally. Quantis estimates that apparel makes up 6.7% of the world’s greenhouse gas emissions, rising to 8% when footwear is included, which is almost four times the estimated emissions from the airline sector.

The fashion industry is failing to meet the 1.5˚C target outlined in the United Nations Paris Agreement by a staggering 50%, placing the industry on a 3˚C trajectory.

A key principle of the circular economy focuses on eliminating waste and keeping materials in circulation at their highest value. By promoting existing infrastructure, rapidly upscaling emerging technologies and pushing for circular business models that genuinely reduce consumption, stakeholders can drive forward collective change.

Based on the research collected from over 50 interviews with prominent cross-sector stakeholders and a comprehensive literature review, this report seeks to uncover common barriers inhibiting progress and propose tangible, actionable recommendations specific to each group.

Why circularity is an urgent need

According to the authors of the report, when it comes to sustainability, about one third of the fashion industry has yet to take action at all. With total clothing sales expected to reach 160 million tonnes by 2050 – more than three times today’s amount, the urgency for change towards sustainability is only obvious.

The fashion industry is failing to meet the 1.5˚C target outlined in the United Nations Paris Agreement by a staggering 50%, placing the industry on a 3˚C trajectory.

A key principle of the circular economy focuses on eliminating waste and keeping materials in circulation at their highest value. By promoting existing infrastructure, rapidly upscaling emerging technologies and pushing for circular business models that genuinely reduce consumption, stakeholders can drive forward collective change.

Based on the research collected from over 50 interviews with prominent cross-sector stakeholders and a comprehensive literature review, this report seeks to uncover common barriers inhibiting progress and propose tangible, actionable recommendations specific to each group.

Why circularity is an urgent need

According to the authors of the report, when it comes to sustainability, about one third of the fashion industry has yet to take action at all. With total clothing sales expected to reach 160 million tonnes by 2050 – more than three times today’s amount, the urgency for change towards sustainability is only obvious.

The industry in 2018 produced 2.1 billion tonnes CO2eq. This represents 4% of global carbon emissions – an emissions share larger than that of France, Germany and UK combined. A report published by the European Regional Development Fund explained that from the 47 targets set in 2017 by brands for 2020, merely 11% of them were achieved by July 2019.

To achieve a step change in sustainability through innovation by 2030, the fashion industry needs US$ 20-30 billion of financing per year to develop and commercialise disruptive solutions and business models that will meet shifting consumer preferences and regulatory pressures.

To stay within a 1.5 degree pathway as recommended by the Intergovernmenal Panel on Climate Change (IPCC), the fashion industry also needs to bring the share of mechanically recycled (or equivalent) fibre or filament within the polyester market from 14% to 90% by 2030.

Utilising current textile-to-textile recycling technologies itself can deliver a 75% increase to circularity in the industry. Less than 1% of material used to produce clothing is recycled into new clothing.

The following eight points represent the most important overarching actions to promote a systemic transformation in the fashion industry to tackle the growing problem of textile waste. The report suggests that all eight priority actions must be pursued simultaneously in order to achieve timely net-zero emission goals.

The industry in 2018 produced 2.1 billion tonnes CO2eq. This represents 4% of global carbon emissions – an emissions share larger than that of France, Germany and UK combined. A report published by the European Regional Development Fund explained that from the 47 targets set in 2017 by brands for 2020, merely 11% of them were achieved by July 2019.

To achieve a step change in sustainability through innovation by 2030, the fashion industry needs US$ 20-30 billion of financing per year to develop and commercialise disruptive solutions and business models that will meet shifting consumer preferences and regulatory pressures.

To stay within a 1.5 degree pathway as recommended by the Intergovernmenal Panel on Climate Change (IPCC), the fashion industry also needs to bring the share of mechanically recycled (or equivalent) fibre or filament within the polyester market from 14% to 90% by 2030.

Utilising current textile-to-textile recycling technologies itself can deliver a 75% increase to circularity in the industry. Less than 1% of material used to produce clothing is recycled into new clothing.

The following eight points represent the most important overarching actions to promote a systemic transformation in the fashion industry to tackle the growing problem of textile waste. The report suggests that all eight priority actions must be pursued simultaneously in order to achieve timely net-zero emission goals.

- Scale collection and sorting infrastructure

- Invest in recycling infrastructure

- Reduce production and consumption

- Establish comprehensive cross-sector collaboration

Interviews with 51 prominent stakeholders revealed that 76% of all interviewees cited the importance of collaboration in achieving circularity.

Interviews with 51 prominent stakeholders revealed that 76% of all interviewees cited the importance of collaboration in achieving circularity.

- Design for durability and recycling

- Promote industry standardisation and universal definitions

- Divest from fossil fuels

- Change the metrics of success

A circular economy is regenerative by design. Defining its success will need to be framed not only through financial metrics but by the improved health of communities and the ecosystems – measured through triple bottom line accounting. By valuing waste as a resource, calculating materials’ true environmental and social costs and decoupling growth from resource consumption, companies should expect a complete overhaul of their business operations. Bold commitments with clear implementation strategies will help businesses, governments and investors navigate new ESG goals.

Conclusion

Circularity when viewed as a whole has the potential to revolutionise the fashion industry and create impactful, positive change for people, planet and profit. Everyone has a role to play when it comes to minimising and better utilising textile waste. From brands to citizens, investors to governments, the final destination of textile waste needs to evolve beyond the landfill. Companies committed to embracing circularity will become leaders in the industry and demonstrate that sustainability can be more than just a marketing buzzword.

A circular economy is regenerative by design. Defining its success will need to be framed not only through financial metrics but by the improved health of communities and the ecosystems – measured through triple bottom line accounting. By valuing waste as a resource, calculating materials’ true environmental and social costs and decoupling growth from resource consumption, companies should expect a complete overhaul of their business operations. Bold commitments with clear implementation strategies will help businesses, governments and investors navigate new ESG goals.

Conclusion

Circularity when viewed as a whole has the potential to revolutionise the fashion industry and create impactful, positive change for people, planet and profit. Everyone has a role to play when it comes to minimising and better utilising textile waste. From brands to citizens, investors to governments, the final destination of textile waste needs to evolve beyond the landfill. Companies committed to embracing circularity will become leaders in the industry and demonstrate that sustainability can be more than just a marketing buzzword.

Textile Excellence

If you wish to Subscribe to Textile Excellence Print Edition, kindly fill in the below form and we shall get back to you with details.