Life Is Simple, Keep It That Way

“I took a bullock cart ride, I walked through lush green farms.” That’s probably a tourist’s rustic holiday, relaxing and enjoyable.

But what if a textile engineering post-graduate from one of India’s prestigious textile engineering institutes had to travel this way as part of his job?

The 1980s was a time when India was moving towards economic development, but mofussil India still lived in relative isolation. There was no good rail and road connectivity to these areas, air connectivity was unheard of. So how and why would one travel to these rural areas to sell modern textile machines?

With B.K. Goenka, Chairman of Welspun India, at the Welspun stall in Domotex, Hannover. His relationship with Mr. Goenka dates back to year 1993.

With B.K. Goenka, Chairman of Welspun India, at the Welspun stall in Domotex, Hannover. His relationship with Mr. Goenka dates back to year 1993.

The how – unimaginable today. The Why – truly inspiring. It was around 1985-87 when this salesperson working in a reputed textile engineering company, would travel to rural Maharashtra from Mumbai, at every given opportunity. “Those were the years when cooperative spinning mills were being set up in the interiors of Maharashtra. I had to travel to these areas.” And how! “The cooperative mills were coming up in the interiors of Maharashtra, which was largely untouched by decent infrastructure and connectivity of any sort. I would take a train, sometimes unreserved seat, to the nearest junction.” And from there by car? “Of course not. After getting down from the train, my only means of travel would be first a local state transport bus and then perhaps in some jeep or in some cases even in a bullock cart, if I managed to hail one. And the bullock cart would leave me till a certain point. After that, I would walk, across fields, to reach my destination. In these small villages, people take 3-4 hour lunch breaks. So, if I reached the mill at 1 pm, I would have to wait till 4 pm to meet the people. And then travel back, or stay in some excuse for a hotel. There were times when I was on the road, travelling for 2-3 days at a stretch.”

With his mentor late Mr. Atul Bhagwati, Chairman of A T.E. Group.

With his mentor late Mr. Atul Bhagwati, Chairman of A T.E. Group.

What was the motivation for Mr G.V. Aras to take such arduous journeys, frequently at that, when he didn’t really need to. “These bullock cart journeys sure paid off. I wasn’t getting orders for machines at that time because many of the mills were not doing well. But I kept on visiting at regular intervals and the relationships were getting built. These millowners or managers would recognise the obstacles I overcame to reach them, as well as my sincerity in visiting them without any possibility of business prospects; it showed my commitment to my work and towards them. I also became a means of information, because I was bringing information from the industry elsewhere and from the big city. Some millowners would discuss their factory problems with me, some would tell me how they had done something innovative. I was also the means of disseminating such information among them.”

“People who have gone from place to place, carrying a bag in their hand, the hard way, they are the ones who built a strong foundation not just for themselves, but also for the organisations they worked in.”“Some millowners and managers would invite me to their home for meals, or bring me meals from their homes. Many of the cooperative mill owners were politicians and would make it a point to meet me when they visited Mumbai. I had developed close relations, even family relations with them.”

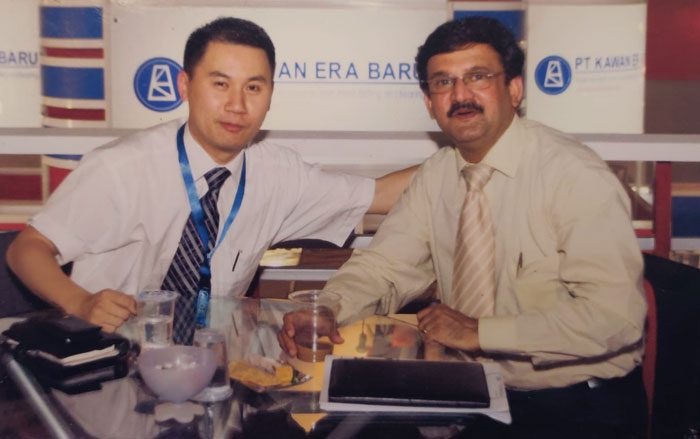

With Walter Leung, Sales director of Fongs Group and an old friend.

With Walter Leung, Sales director of Fongs Group and an old friend.

The result - “When the mills were ready to invest, Trumac (Truetzschler today) was their only choice. For 5-6 years, Trumac enjoyed 100% market share in some of the territories where these mills were located, others could not sell even a screw there.” “The words of this one customer have stayed with me till today, and have been my motivation: `There are two reasons why I place orders with you - Number one, when we were not in the market to buy machines, when things were not going well for us, hardly anybody came to us. Except you, you were always here, whether there is business or not. That shows that you never work for business alone, you work for building relationships. So when I evaluate my investment decisions, you are the first person that comes to my mind.

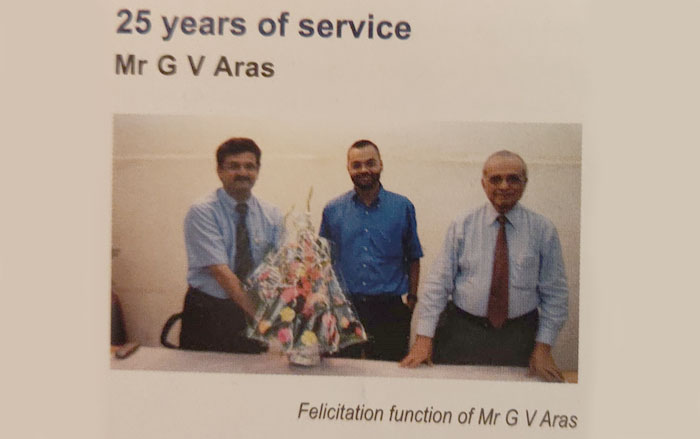

Felicitation from Chairman late Mr. Atul Bhagwati on completion of 25 years service on October 15, 2006.

Felicitation from Chairman late Mr. Atul Bhagwati on completion of 25 years service on October 15, 2006.

`And number two, people don't buy machines, people buy comfort, people buy solutions. If I encounter a problem, the blowroom stops functioning and the entire mill operation comes to a halt, I know I can depend on you. I know I can call you in the middle of the night, confident that you will immediately take action, and I can peacefully go to sleep. This is the confidence I have in you, which I don’t have in the others.’ “This was a great learning lesson for me. I learnt that these are the two most important things – people buy comfort, not machines. And people value honest relationships. If you take care of these two aspects, business becomes a by-product.” And another important lesson – hard work pays, it’s always proven to. For this generation, this kind of work is unimaginable. “I would have to say that this generation is born with a silver spoon. They have all the possible facilities, excellent means of communication and information at their fingertips.

On the occasion of delivering 10000th Indian made Truetzschler card from the Truetzschler India factory.

On the occasion of delivering 10000th Indian made Truetzschler card from the Truetzschler India factory.

“Having said that, there are other challenges today. The customer is better informed today. He does his homework, evaluates all options and solutions before meeting you, and you have to be on top of your game. Earlier the information flow was limited. We had a bit more information about our machines than our customer. The competition is way more intense today. But life is more comfortable too. “People who have gone from place to place, carrying a bag in their hand, the hard way, they are the ones who built a strong foundation not just for themselves, but also for the organisations they worked in.” The unglamorous textile industry keeps us glued

Striking The Work-Life Balance “In our quest to reach the top of the ladder, we forget that we have a precious life, we have a family. I myself have always tried to strike a balance in my work and my life. I always used to tell my team to remember one thing: Family First. If something happens to you, the company can replace you easily, but can your family do the same? So, while you are working like crazy, travelling, spending all your time on the mobile, laptop, keep this in mind – family is far more important. “I know in the demanding corporate world, it’s difficult, but I always tried to give quality time to my family, and especially my children. I feel there is a mismatch that needs to be seriously addressed: when we are at the peak of our careers, we have no time for the family, but when we retire and our children are at the peak of their careers, they will have no time for us. So, address this while you still can. “Another thing I always used to tell my teams in textile engineering group at A.T.E.: Nothing is urgent in the capital machinery business. Orders take six months to a year to finalise. So there is no necessity to push yourself to the wall.”The textile industry is a difficult industry to be in, hard work, shop floor work, unglamorous work. Why would a first class student want to opt for textile engineering and a career in this industry?

“Textile engineering was not my first choice. I wanted to do chemical engineering, but missed it by one mark. And I was not interested in the other fields of engineering which are too generalised. So, I decided to go for textile engineering, and everyone around me encouraged me too.” Mr. Aras stood first in Mumbai University in all the four years and was a gold medallist too. Job offers had begun pouring in, but he opted for M.Tech, on his father’s advice – `Jobs will be there, this is the time to study and build the foundation.’ Even before he could complete his thesis on Influence of Some Spinning Process Parameters which also included fibre handling at blow room, he was offered a job by some of the leading companies in this segment. One of them was planning to make blow room lines in India. So he preferred to join A.T.E Enterprises (erstwhile Associated Textile Engineers), which had a plan to make Truetzschler blow room machines in India, even as he was just completing his thesis. For Mr Aras, A.T.E. was a great fit, as his work involved visiting customers, effecting sales. “I love to meet people, nurture relationships, I find it enjoyable to talk with people, learn from them, exchange views and ideas. And anyone with this flair is best suited for sales.” But Mr Aras had never imagined that he would complete more than 40 years in this company. “My friends had changed 2-3 jobs in 10 years, and I was still with this one company. They would joke that I would retire from here. And it turned out to be true. It’s just that every time I had an offer, a better opportunity presented itself in A.T.E. Also, my father’s words were guiding me: `These initial years are for building your foundation brick by brick. That will help your career. Money cannot be the guiding criteria.’ And I realised every time that A.T.E. was the best option for me to build my career, to learn, and grow. “My parents lived a simple life, this was my upbringing too, I love the simple things in life, I love simplicity in life. And I believe in giving more than 100% to any job I do. I think it’s all these factors that have led me to my success.” `I learned the value of hard work by working hard’ Mr Aras’s consistent hard work paid off in more ways. “I had been with the company for just 10-12 years,” states Mr Aras humbly, even as most of us would have changed 2-3 jobs in the race to the top in these years. “In those years, Trumac was an unknown brand and it required quite some effort to establish the brand – years of extensive traveling and discussing technicalities of our technology. I worked very hard to sell the first German made Truetzschler card DK-740 in India under guidance of then sales head of Truetzschler, Germany Mr Karl Roettegering (who also acted as my mentor for some years). Finally, we met our first grand success after many years of hard work, in selling 8 Truetzschler DK-740 cards from Germany to Bombay Dyeing. That laid the foundation for launching Indian made DK-740 card five years later,” recollects Mr Aras about the achievement of the major milestone.

At India ITME 2012 with Truetzschler Managing Directors Dr Schuerenkraemer, Mr Truetzschler and Mr Khandelia of Sutlej Group.

At India ITME 2012 with Truetzschler Managing Directors Dr Schuerenkraemer, Mr Truetzschler and Mr Khandelia of Sutlej Group.

And he was involved hands-on in the development of the card, the brand, the market. “This was indeed a grand opportunity that came my way while I was working very hard in sales, which proved to be the breakthrough for my career at Truetzschler. The company wanted to start making carding machines in India, and decided to appoint me to lead the team. I was still quite junior at that time. As product manager, I was given complete charge of this new project. The machine was successfully built in India, we worked hard to launch the card, the DK 740 model, which went on to become quite popular in the industry.” Mr Aras did not rest on his laurels. “As a manager, I did not need to travel, I had a sales team. But I had already learned the importance of relationships and networks. So I continued to travel, to keep up-to-date on what’s happening in the industry, also to understand and observe how my team was interacting with customers. This got me quite close to my sales people, I knew their strengths, their weaknesses and could thus work with them to get the best results.”

`Sales go up and down, service stays forever’

“Ah, this is an interesting tussle, if at all. I learnt from our chairman Mr Atul Bhagwati that service has to be of prime importance, because one dissatisfied customer can spread the negative news across the industry. He told me to always attend to the service complaints before all else, service must be prompt. And that is true, the first sales will be done by the sales team, but consequent sales are done on the basis of your service to your client.” And strong service is the biggest success factor for A.T.E. Enterprises. “We have a very big sales team, we train them, invest in them – right from how to talk with customers, how to handle difficult situations and customers, while of course, giving the best service. I can truthfully boast here that some of the most difficult customers that I had to deal with overtime became my friends, and I became their favourite person. I am proud of this achievement.” “In these training sessions, I always used to tell my team that when a customer is unhappy, the situation becomes quite complex, and we have to start from a level of -20, not zero. From -20, we have to bring the situation to zero, and then build from there. And scientifically it is proven that one negative incident needs at least 10 positive experiences to remove the impact of that one event.”

At India ITME 2016, with Truetzschler Managing Directors Dr Schuerenkraemer and Mr Truetzschler.”

At India ITME 2016, with Truetzschler Managing Directors Dr Schuerenkraemer and Mr Truetzschler.”

`Mistakes – Admit it, learn from it, don’t repeat it’ Mr Aras narrates a rather harrowing and dramatic, but interesting incident, when he was President, at A.T.E Enterprises. “This is a very big textile company today. The chairman of the company sent his son along with senior managers to our office. And something happened at the meeting, my senior who was there had some trouble with this customer, and told him that he was not willing to supply the ordered machines and they can go to the competitor to buy the machines. This was a flashpoint. The customer said : `I don’t want to buy anything from A.T.E anymore, want nothing from A.T.E.’ It was the end of the story for us. “My sales team asked me to intervene, it was just not possible for us to lose this customer. I went to this client’s office, and with the help of their manager, was able to enter the chairman’s cabin. The moment he saw me he said - `I don’t want to even see your face, get lost! I don’t want to talk with anybody from A.T.E.’ I fervently requested him for five minutes of his time, he declined firmly. He realised I wasn’t going to leave his cabin, so he walked out and went to his car to leave. His manager told me - `Mr Aras, if you want to resolve this issue, this is your last chance, you have to stop him from leaving’. “I went running after him, caught up with him as he was about to sit in his car, I held on to the car door. And pleaded with him for those five minutes again. I told him I did not want anything from him, but for him to listen to what I had to say, and decide after that. It was my good fortune, or he probably saw the sincerity on my face, he relented. I apologised fervently and unconditionally, and took full responsibility for what happened. He probably saw the truthfulness in me and said : `Mr Aras I like you, there are very few people in the industry who will admit to a mistake.’ “And the next time he had a requirement for machines, he called me. I’m proud that I could build a one-to-one relationship with this person in a way that he could repose his confidence in me. This was sometime in 2008-09, and by the time I retired in 2021, we had done business of over Rs 300 crore with this company. The bond remains strong to this day.”

But was it not humiliating to do this, as president of a company, when it wasn’t even your fault?

“Well, we had insulted them, hurt their self-respect. And I always profess humility. One must know how to handle and address emotions. I believe that in the textile industry, you can achieve nothing if you have an ego. You can be a big shot, but you need to stay grounded at all times. You have to realise that you are just a drop in the ocean.” However, not every incident ended in such success. “There were times when we had to face problems, and deteriorating relations with our customers because of some of the principals that we had joined hands with. These were judgmental errors as I was trying to make A.T.E a one-stop textile technology solution. And so, we sometimes partnered with companies that did not meet our standards. In this, I learned that you have to partner with the best, and not the mediocre. And if you have, but realise the mistake, it is necessary to end that business relationship at the earliest, before it starts to impact your company’s reputation. Luckily at A.T.E we always had a Plan B ready, so the issues never really got out of hand.”

Receiving the Service Gold Medal of year 2018 from Chief Guest Dr Dinkaran, Chairman, Ramlinga Group of Mills at International Textile Conference in Coimbatore in August 2018.

Receiving the Service Gold Medal of year 2018 from Chief Guest Dr Dinkaran, Chairman, Ramlinga Group of Mills at International Textile Conference in Coimbatore in August 2018.

Fulfilling aspirations

“I had no aspirations. I am not an ambitious person at all.” But how does one measure aspirations and their fulfilment? “When I look back, at my career of more than 40 years, I feel immensely satisfied – I have received a lot of love, respect, recognition from this industry. I myself could not believe the farewell functions and ceremonies organised for my retirement by my company, my team, my principals, my customers. This is a lifetime achievement for me. I started as a junior sales executive in A.T.E and moved up the ladder to become the director. But anyone in my place would have achieved this, given the opportunities. End of the day, I feel very happy because people have trusted me, I have gained their trust by being sincere and truthful. Post my retirement, I have received so many offers from India and abroad for being an advisor and also from some for joining the board of directors. This is very humbling.”

Preparing the next generation for this industry

“I believe it is no longer true that youngsters are not attracted to this industry. Look at all the start-ups that are coming up in this industry. All by youngsters. They are reshaping the way the industry works. It is indeed very encouraging to see their enthusiasm. We can say all the boring things about this industry, but today we have great leaders, great talent in this sector. I am hopeful for this industry.”

.

If you wish to Subscribe to Textile Excellence Print Edition, kindly fill in the below form and we shall get back to you with details.