Adidas Uses TrusTrace Traceability Platform At Scale

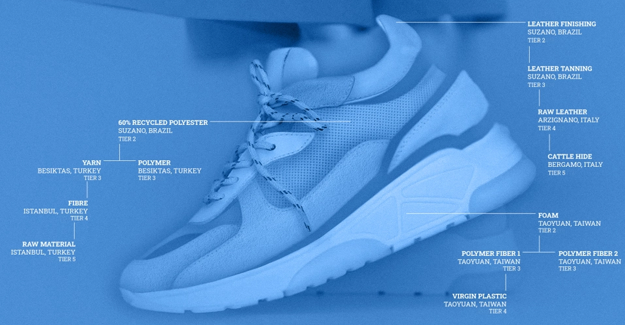

Global sports brand adidas is one of the first large businesses in the footwear and apparel sector to achieve material traceability at scale, gaining greater visibility into its complete supply chain down to the material level, by using TrusTrace’s digital traceability platform. Challenge 1: Race to trace sustainable materials As part of a commitment to sustainability, Adidas has set targets to source 100% recycled polyester, the most common material used in Adidas products, by 2024. By 2025, Adidas is also aiming for 9 out of 10 of their articles to be sustainable, meaning that they are made with environmentally preferred materials. Adidas is leveraging material traceability to track and create a digital chain of custody for the use of certified materials, such as organic cotton or recycled polyester, in every batch of production across its supplier network. Challenge 2: Traceability that scales with a global giant With objectives to trace all products and materials across apparel, footwear, and accessories divisions, Adidas had to ensure that the traceability solution could cover large amounts of data, meaning a digital, automated, and scalable solution. With many transactions and data points from multiple systems, manual data entry was not an option. Solution: Integrated and automated material compliance and traceability Adidas chose Certified Material Compliance and they've integrated their systems with TrusTrace, ensuring seamless data flow between PLM, Purchase Order System, and Supplier Management systems. Besides automated data flows, the integrations also ensure data quality, as the data is continually updated, capturing last minute changes to designs or purchase orders. Adidas and the TrusTrace Business Services team also worked in tandem to onboard hundreds of suppliers and get them familiar with how to share documentation on TrusTrace within the first months. The Results Using material traceability data, Adidas has achieved better visibility and control of their supply chain data, and can ensure that compliance needs are met. Adidas collects all the supply chain data in real time as the materials flow through the value chain, meaning that the final product has all the data attached to it when it arrives on the market. With this data, Adidas checks the finished product vs. the original design/purchase order, ensuring that everything has been produced as planned, and can then easily provide evidence for product or material claims. Through a strong focus internally and in collaboration with their suppliers, Adidas was able to implement and scale the traceability program within months.

Textile Excellence

If you wish to Subscribe to Textile Excellence Print Edition, kindly fill in the below form and we shall get back to you with details.