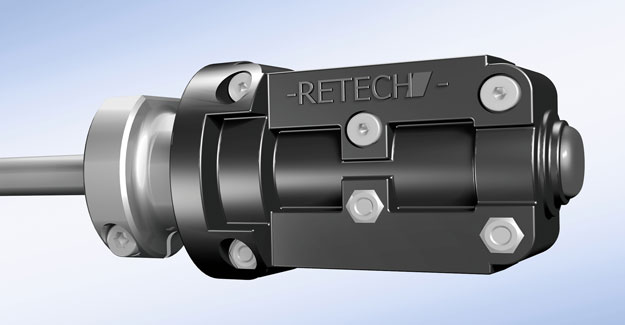

Retech Technology Innovations Underline Its Expertise In Filament Production

Temperature Control – Every Degree Matters Perfection in drawing fibres is Retech’s simple goal. But achieving this for its customers demands sophisticated technology in temperature transmitters, monitoring devices and controllers, to allow precise heat management for high-quality products, while protecting machine investments. Precise temperature measurement and control are basic requirements for the ‘perfect’ fibre – and absolutely crucial for high-performance yarns. Retech has the technology to secure the ideal temperature and control every aspect of it, even for the most demanding applications. Every Retech development is the result of comprehensive research and practical expertise. Its trio of innovations for godet roll temperature management are typical: they are precise, reliable, easy to handle, and durable, supporting Industry 4.0 and securing the client’s investment. No other godet roll manufacturer can match these sophisticated and smart temperature control solutions. Technology for ultimate temperature accuracy Temperature transmitters are mainly applied with multi-zone heated godet rolls. They work by contactless induction data transmission. The temperature modules transmit a rotating temperature signal to a stationary receiver. Retech temperature transmitters are proven to operate in the harshest electromagnetic environment. Pollution, high outside temperatures and aging don’t influence the precision of temperature measurement. Retech components ensure unadulterated temperature data. Measured values are transmitted contactlessly to the static part of the godet roll. This prevents contamination or wear and tear from influencing measuring data. Secure way to Industry 4.0 For perfect data security, Retech offers the UTL monitoring device, which analyses the data and integrates it in the communication protocol. Benefits arise from a comprehensive view of all temperature aspects, visualising and controlling temperature values at each zone, the bearings and the inductor via the host system. The UTL guides filament yarn producers toward Industry 4.0. The combination of the temperature transmitter and the UTL monitoring device creates a unique safety system. It controls all relevant temperature aspects, enabling appropriate action in the event of a deviation. From control to self-optimisation Self-optimisation is the major advantage from combining the system with the UCR-6 temperature control unit. UCR-6 independently monitors and regulates up to six different temperature zones of a godet roll. Featuring a completely new control algorithm, the unit delivers the most efficient energy consumption, as it compensates losses at the heating zones. UCR-6 continuously collects and analyses data from the mains frequency, so that it can correctly switch solid-state relay for resistive and inductive loads. The control unit can communicate with a PLC via Profibus or RS-485 protocol. Users appreciate the extra visualisation of values and settings on the integrated controller display. Retech’s new generation of UTR temperature transmitter and UCR temperature controller represent the summit of current technological developments. They make a great leap towards self-optimization of the whole godet system, in a way that secures a long service life as well as protecting the equipment. Overall, they optimize production processes and significantly increase yarn quality.

Temperature Control – Every Degree Matters

If you wish to Subscribe to Textile Excellence Print Edition, kindly fill in the below form and we shall get back to you with details.