PLEVA’s Innovative Solutions For Efficiency And Sustainability At India ITME

In times of rising energy prices and discussions on cost reductions as well as sustainability, practical solutions are required. PLEVA as a long-term expert for sensor technology and process optimisation offers solutions for various applications. The latest innovations for efficiency will be presented at India ITME in hall H5 booth H11 and PLEVA is looking forward to a successful exhibition: “India is a keymarket for us and we are happy to participate at India ITME. It is a great place to get in touch with customers and get new insights about the market”, states Sales and Service Director Volker Müller. “We are excited to introduce our high-tech technologies: the weft-straightener SL smart, our sustainable solution for sizing AS 120, and our process visualization and control system PLEVATEC smart.”

SL smart

[caption id="attachment_25336" align="aligncenter" width="700"] PLEVA SL Smart[/caption]

The straightening machine SL smart is designed for knitted and woven fabrics with a plurality of solutions customisable to fit the individual customer needs. It includes several options for customisation like fully-integrated accessories for tension-sensitive fabrics, Industry 4.0 applications and more. The heart of the SL smart is the well-established traversing camera technology which is unique in weft-straightening. The universal high-resolution camera captures up to 20 measuring points per meter of fabric width. This gives a complete overview of the fabric instead of few fixed positions. Finally, advanced evaluation algorithms ensure an ultra-precise distortion analysis which enable perfect straightening results in a blink of time.

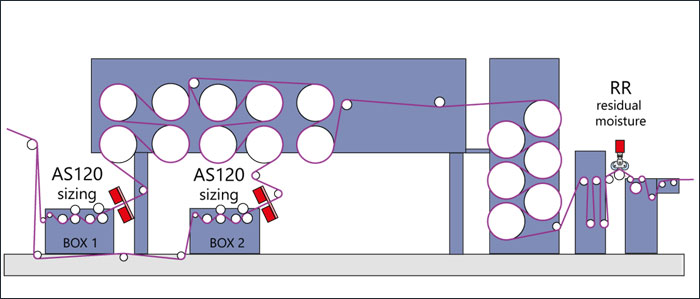

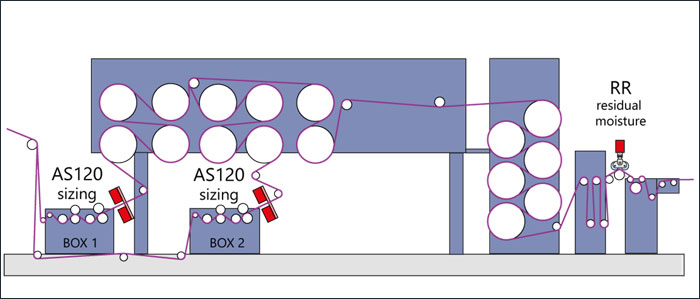

AS 120

[caption id="attachment_25335" align="aligncenter" width="700"]

PLEVA SL Smart[/caption]

The straightening machine SL smart is designed for knitted and woven fabrics with a plurality of solutions customisable to fit the individual customer needs. It includes several options for customisation like fully-integrated accessories for tension-sensitive fabrics, Industry 4.0 applications and more. The heart of the SL smart is the well-established traversing camera technology which is unique in weft-straightening. The universal high-resolution camera captures up to 20 measuring points per meter of fabric width. This gives a complete overview of the fabric instead of few fixed positions. Finally, advanced evaluation algorithms ensure an ultra-precise distortion analysis which enable perfect straightening results in a blink of time.

AS 120

[caption id="attachment_25335" align="aligncenter" width="700"] PLEVA AS 120[/caption]

Sizing is the crucial preparation for weaving and high yarn quality. Therefore, sizing agents are applied with a squeezing unit to the warps. To be on the safe side often 10-25% more sizing is applied than required. This implies disadvantages like higher use of expensive sizing agents, more wastewater, unstable yarn quality, lower weaving efficiency, etc. To eliminate those disadvantages, a measurement and control is needed. The AS 120 measures the size add-on after size box constantly. It includes a special construction with integrated protection against steam vapours and high temperatures. This enables a reliable, continuous monitoring and control. As a result, 1.5% up to 4% higher weaving efficiency is easily possible.

PLEVATEC smart

[caption id="attachment_25337" align="aligncenter" width="700"]

PLEVA AS 120[/caption]

Sizing is the crucial preparation for weaving and high yarn quality. Therefore, sizing agents are applied with a squeezing unit to the warps. To be on the safe side often 10-25% more sizing is applied than required. This implies disadvantages like higher use of expensive sizing agents, more wastewater, unstable yarn quality, lower weaving efficiency, etc. To eliminate those disadvantages, a measurement and control is needed. The AS 120 measures the size add-on after size box constantly. It includes a special construction with integrated protection against steam vapours and high temperatures. This enables a reliable, continuous monitoring and control. As a result, 1.5% up to 4% higher weaving efficiency is easily possible.

PLEVATEC smart

[caption id="attachment_25337" align="aligncenter" width="700"] Plevatec Smart[/caption]

The customisable process control and visualisation system PLEVATEC smart is designed for versatile use for various finishing and drying processes. It enables an integration of the well-known sensors for exhaust air humidity (FS X), fabric temperature (TDS), pick/course density (CAM), residual moisture (RR) and the weft-straightener (SL smart). It is perfect for retrofitting to enhance older machines to maximum efficiency with intuitive operation. The modular solution helps to get a good overview as well as to optimize critical process parameters to produce more stable and sustainably.

Plevatec Smart[/caption]

The customisable process control and visualisation system PLEVATEC smart is designed for versatile use for various finishing and drying processes. It enables an integration of the well-known sensors for exhaust air humidity (FS X), fabric temperature (TDS), pick/course density (CAM), residual moisture (RR) and the weft-straightener (SL smart). It is perfect for retrofitting to enhance older machines to maximum efficiency with intuitive operation. The modular solution helps to get a good overview as well as to optimize critical process parameters to produce more stable and sustainably.

Textile Excellence

If you wish to Subscribe to Textile Excellence Print Edition, kindly fill in the below form and we shall get back to you with details.