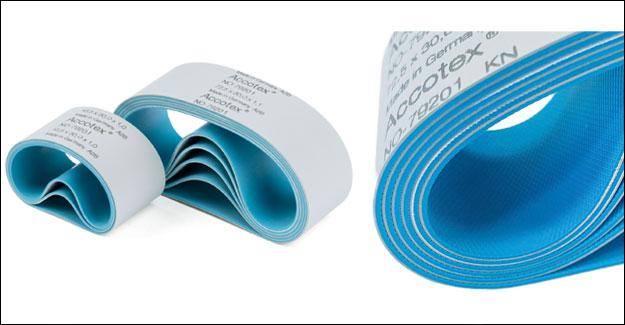

Field Tests Confirm High Performance Of New Accotex Aprons

The latest Accotex apron NO-79201 is made from new compounds that deliver longer life and better performance. Flexible enough to work with all fibre types across ring and compact-spinning machines, field trials show better resistance throughout a 12-month spinning cycle. The NO-79201 is available in a wide range of dimensions as top and bottom aprons for all kinds of applications. The Accotex NO-79201 (Fig. 1) is a new generation of aprons for ring and compact spinning machines. It is made of two aligned rubber compounds which deliver a high abrasion and crack resistant spinning apron. The mechanical robustness of the rubber compounds allows effective use on all ring and compact-spinning machines, working with all fiber types and within the whole spectrum of yarn counts. The excellent friction properties of the compound contribute to a smooth and even running over the whole service life of the apron, especially at the start-up of machines. Superior friction behaviour The new Accotex NO-79201 was tested for 12 months at a customer in the USA, alongside the already existing NO-78210GX, the NO-78210G and a competitor’s apron (Fig. 2). The friction value of the different aprons was measured over the whole life in regular frequencies. Each column reflects the individual friction value of the inner layer evaluated on representative apron samples from the field test at 3, 6, 9 and 12 months. After 12 months running, the inner layer friction of the new NO-79201 is nearly unchanged, confirming the smooth and even running over the whole service life of the apron. This superior friction behaviour has also been reported from other Accotex customers across the world, processing different fibre types, blends and yarn counts. Besides, these trial customers have noticed far fewer broken bottom aprons than they would normally expect. Different versions for flexible use The Accotex apron NO-79201 is available in a wide range of dimensions as top and bottom aprons for all kinds of applications. It comes as closed apron, skived bottom apron or skived and pre-glued bottom apron. The NO-79201 can be supplied with a plain inside or a specially configured inner layer pattern, known as a knurled version (Fig 3). The main benefit of the knurled apron is to provide less contact area to the nose bar, which enables lower torque, and thus less stress on the bottom roller bearings. This also allows the inside structured apron to run clean on so-called “dirty” fibres and to work efficiently in demanding environmental conditions in terms of fibre cleanliness. The knurled apron is available with diameters of 72.5, 76.3 and 79.0 mm. Overall, the new Accotex NO-79201 spinning apron provides improved performance for ring and compact-spinning with less machine downtime. Its flexible application may also reduce stocking levels and simplify servicing regimes.

Textile Excellence

If you wish to Subscribe to Textile Excellence Print Edition, kindly fill in the below form and we shall get back to you with details.