LMW's Technology-Based Solutions Meet Demand For Automation, Digitalisation, Analytics, Sustainability

The textile industry is moving ahead with capacity creation and expansion investments, preparing for when demand picks up in the next few months. And in this, India's spinning industry is gravitating towards the technology-based solutions offered by LMW.

LMW's focus on customer centricity and perfect alignment with market trends has helped it offer the best spinning technologies, packed with automation, digitalisation, analytics, and sustainability – features that are most sought after by spinners.

LMW remains optimistic in a market that is facing challenges. India's cotton and yarn prices have witnessed volatility in the last few months, pushing the industry towards production cuts.

Despite this development, investments in the textile industry are continuing, and planned investments are being completed on time. The industry is cautious about keeping capacities ready once the markets pick up. The Indian industry players know that textile is a basic necessity so that demand will gather momentum after any downturn.

Moreover, given the emerging geopolitical situation, India is in an advantageous position to fulfil a significant part of global demand. And that's an important reason why textile investments are continuing in India.

In this scenario, LMW has been busy executing orders that were already booked and, in fact, pushing its resources to ensure the timely delivery and installation of machines.

When is a turnaround expected?

Some of LMW's important global markets - Bangladesh, Turkey, Indonesia, Vietnam, and some African countries – are all facing a severe energy crisis thanks to rising energy costs. Higher energy costs mean reduced profitability.

And on the other side, demand for the end product – apparel – is sluggish. With unprecedented inflation rates in the US and Europe, consumer confidence has been severely impacted, resulting in low demand for clothing. This has meant that retailers have been holding large amounts of inventory for the last 5-6 months.

However, we have to remember textiles are an essential industry and will recover over time. Hence the textile industry players know that the current situation is challenging but temporary, and once demand picks up, costs will get passed on. This is widely expected to happen by early 2023.

The expected slowdown and India ITME 2022

Despite the slowdown in the textile industry, exhibitors and visitors are looking forward to India ITME 2022, which is happening after a gap of six years. It is also the first major textile event after Covid. For LMW, this is, as usual, a great platform to showcase its latest innovations and meet customers, friends and competitors.

The Indian textile industry has been investing in automation, but this trend and the need for it became stronger during the Covid lockdown period.

The industry has gradually warmed up towards technology that offers automation, digitalisation, analytics, forecasts, and interpretations. LMW is ready with its latest machinery that provides the industry's expectations.

The company also expects many international visitors from its important markets - Bangladesh, Indonesia and Vietnam. Textile manufacturers from these countries will want to see the latest technology and trends. Moreover, only a few textile technology exhibitions have happened in this region. So India ITME is the perfect platform to exhibit the latest in technology and innovation.

How LMW captured the spinning technology market

The industry's perception of Indian-made Technology and machines has changed in the last few years. LMW, a global leader in spinning technologies, today enjoys a market share of 65-70% in India. Technology-wise, it is among the best in the world, surpassing its competitors in some products. The industry, having experienced LMW products, technology, and service, has shared its testimonials with others in the market.

What is also encouraging for the Indian textile technology makers is that price is no longer the deciding factor in capital goods investment. The industry is OK with spending 15-20% more for the best available technology.

Having achieved the lion's share in the Indian market and a strong foothold in the export markets has made LMW more alert and active. The company is constantly investing in developing differentiated products and solutions that showcase its strengths, edge, and technology.

[caption id="attachment_25585" align="aligncenter" width="700"]

The expected slowdown and India ITME 2022

Despite the slowdown in the textile industry, exhibitors and visitors are looking forward to India ITME 2022, which is happening after a gap of six years. It is also the first major textile event after Covid. For LMW, this is, as usual, a great platform to showcase its latest innovations and meet customers, friends and competitors.

The Indian textile industry has been investing in automation, but this trend and the need for it became stronger during the Covid lockdown period.

The industry has gradually warmed up towards technology that offers automation, digitalisation, analytics, forecasts, and interpretations. LMW is ready with its latest machinery that provides the industry's expectations.

The company also expects many international visitors from its important markets - Bangladesh, Indonesia and Vietnam. Textile manufacturers from these countries will want to see the latest technology and trends. Moreover, only a few textile technology exhibitions have happened in this region. So India ITME is the perfect platform to exhibit the latest in technology and innovation.

How LMW captured the spinning technology market

The industry's perception of Indian-made Technology and machines has changed in the last few years. LMW, a global leader in spinning technologies, today enjoys a market share of 65-70% in India. Technology-wise, it is among the best in the world, surpassing its competitors in some products. The industry, having experienced LMW products, technology, and service, has shared its testimonials with others in the market.

What is also encouraging for the Indian textile technology makers is that price is no longer the deciding factor in capital goods investment. The industry is OK with spending 15-20% more for the best available technology.

Having achieved the lion's share in the Indian market and a strong foothold in the export markets has made LMW more alert and active. The company is constantly investing in developing differentiated products and solutions that showcase its strengths, edge, and technology.

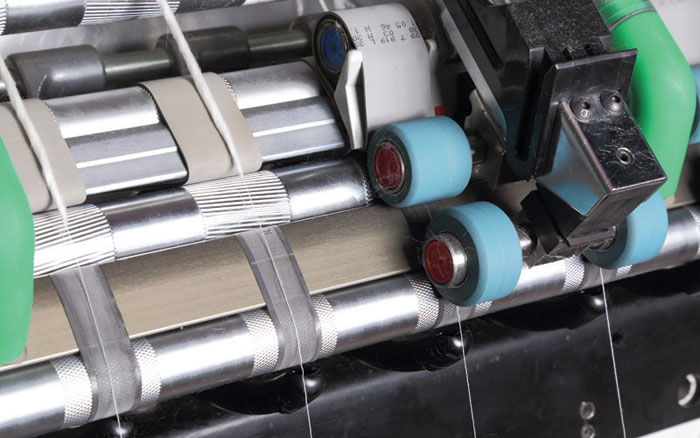

[caption id="attachment_25585" align="aligncenter" width="700"] Spinpact- LMW Compact System[/caption]

The evolving role of technology players

The industry players – textile and technology manufacturers - understand they have an essential role in the country's development. Matching with their readiness, the government has implemented many policies and schemes to help the industry. More such policies are in the pipeline. Gone are the days when the Indian textile industry depended heavily on foreign technology. Of course, some segments in the textile value chain, like garment manufacturing, processing, etc., still rely on foreign technology. Still, here too, Indian manufacturers are expected to bring in indigenous solutions soon.

One area of concern for Indian textile machinery manufacturers is mechatronics. Here the industry is still dependent on imports. Today almost 30-50% of the critical components needed in a machine have to be imported. These parts need to be developed within the country. Here again, the industry will need government support.

LMW's marketing strategy

The company stays focused on being connected with the customers and the markets. LMW's strategy has always been to understand its customers' needs and requirements. This helps the company to discover newer market opportunities.

New materials and LMW technology

Increasingly there is a trend towards newer plant-based, agro-waste fibres. Demand for such fibres is still small but is a growing trend. LMW machines are suitable for such fibres if the fibres are prepared in a specific manner. LMW expects to emerge as a preferred technology partner in this segment and help the industry in its efforts to develop sustainable textiles.

Spinpact- LMW Compact System[/caption]

The evolving role of technology players

The industry players – textile and technology manufacturers - understand they have an essential role in the country's development. Matching with their readiness, the government has implemented many policies and schemes to help the industry. More such policies are in the pipeline. Gone are the days when the Indian textile industry depended heavily on foreign technology. Of course, some segments in the textile value chain, like garment manufacturing, processing, etc., still rely on foreign technology. Still, here too, Indian manufacturers are expected to bring in indigenous solutions soon.

One area of concern for Indian textile machinery manufacturers is mechatronics. Here the industry is still dependent on imports. Today almost 30-50% of the critical components needed in a machine have to be imported. These parts need to be developed within the country. Here again, the industry will need government support.

LMW's marketing strategy

The company stays focused on being connected with the customers and the markets. LMW's strategy has always been to understand its customers' needs and requirements. This helps the company to discover newer market opportunities.

New materials and LMW technology

Increasingly there is a trend towards newer plant-based, agro-waste fibres. Demand for such fibres is still small but is a growing trend. LMW machines are suitable for such fibres if the fibres are prepared in a specific manner. LMW expects to emerge as a preferred technology partner in this segment and help the industry in its efforts to develop sustainable textiles.

Textile Excellence

If you wish to Subscribe to Textile Excellence Print Edition, kindly fill in the below form and we shall get back to you with details.