Modern Set-Up Has Ensured In-House, Quality Production

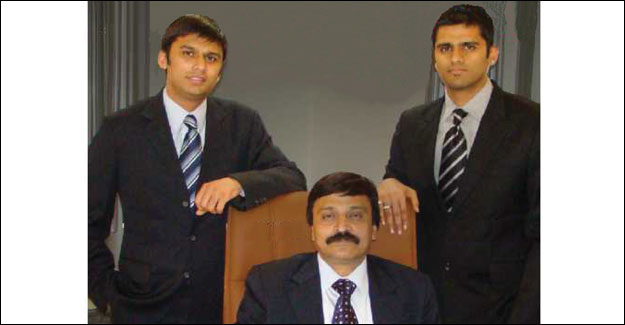

Excellent product quality, quick delivery and prompt after-sales services has ensured a wide customer base, and repeat business from OEMs, for Draft Air. The company, with a strong foothold in a range of sectors, believes that efficient production planning and control, finance management, strategic optimisation of procurement processes and the entire supply chain have helped the company establish itself in the market. In conversation with G.D. Panchal - CMD, Prakash Panchal – MD, Mitesh Panchal – Technical Director, Draft Air. Tell us about some of your innovative products and technologies, and how these are helping the industry? We have brought one of the best technologies in fan and blowers from USA : Chicago Blowers which is known throughout the world for its efficiency and reliability. We are supplying hollow airfoil blades to textile industry for waste recovery plants for blowroom, card and comber which has the highest efficiency and low power consumption. We have done numerous fan replacements in existing waste collection plants where the customers have benefited from huge power savings. With our experience and customer feedback we have innovated products like rotary drum filter by giving double nozzle arrangement per segment which increases the filtering efficiency, reduces pressure drop across filter and hence power consumption. We have done various modifications in existing units and helped the customer save power with our technology. How did you face competition from established world players, and the mind-block of mills that European technology is the best. Yes, this mindset that Indian technology is not up to world class standards is a challenge for us, and others in this field. The truth is that Indian textile technology has come a long way, and we have emerged strong and serious competitors to European brands. Indian textile machinery and accessories installations are increasingly visible across the world. How ahead in terms of technology and market reach are you compared to international competitors? We are a family owned business started in 1986 and hence we don’t have the range of set-up like international competitors. So, comparatively, the market reach is limited, but surely we are getting there slowly and steadily. Our reach is expanding across the country, customers are appreciative of our business practices, ethics, products, service. How has your company emerged successful in this very competitive field? Yes it is very competitive and preference of customers towards international brands makes it even more challenging. It’s a lot of hard work that we are putting in. We always say to our customers that seeing is believing and hence we ask our potential customers to visit our installation and our state-of-the-art manufacturing facility, which we have made after the collaboration. It is equipped with the latest CNC machines, laser cutting, plasma cutting, metal spinning and our fan balancing machines. Our test facility is one of the most up-to-date test stations of its kind. At our location, we offer extensive test services encompassing full load type tests, and system checks – including for external customers and brands. Our test batch panel includes a 1200KW & 37KW converter for all normal voltages from 415V to 11 kV. So, as you can see, we have very modern infrastructure and facilities. With our full-fledged manufacturing facility we’re able to take up all manufacturing activities in-house which is why we have better control on product quality, workmanship and thus better inventory turn. Production planning and control and finance management are our strengths to combat these challenges. Excellent product quality, faster delivery and prompt after-sales services are earning us repeat business from OEMs which constitute about 60% of our total business. Strategic optimisation of procurement processes and the entire supply chain are the key driving factors for the success and that is how we have emerged as one of the market leaders. Where do you envision Indian textile engineering industry in the next five years? India is going to be the future for the world for most of the industries because of the resources we have. Also cost competitiveness gives us an advantage. Besides this, we have very large market available to cater to the requirement not only in India but also in the neighbouring countries as the Indian industry is well trusted for the quality products with competitive price and thus, the Indian industry has established itself as the preferred one over others. India is now known as one of the fastest developing country. Political stability, strong pace of economic growth, improved logistical supports, cost-effectiveness and technological advancement have made the industry a leading exporter and we foresee an exponential growth in coming years. Anything else you would like to share? World class manufacturing facility, energy efficient products and customer delight are the core things we strive hard to achieve. These will be achieved through technological advancement and upgradation of our facility, continuous improvements in our products and surpassing customer expectations through exceptional after sales support. Innovation, people culture and safety are among the things we endeavour to enhance. Creating a culture of trust among all our associates through transparency is the key to success we envisage.

Textile Excellence

If you wish to Subscribe to Textile Excellence Print Edition, kindly fill in the below form and we shall get back to you with details.