Bemberg™ - A Sustainable Choice For Indian Textile Industry

Bemberg™

- A Sustainable Choice For Indian Textile Industry

Sustainable materials have become an

undeniable need of the textile and fashion industry, with the growing

consciousness of environment in the society. Are you aware that Bemberg™ is a

preferred sustainable material, produced from natural source?

Bemberg™ is the brand name of cupro,

a regenerated cellulosic fiber produced by Asahi Kasei in Japan since 1931 and

exported to India for about 50 years. This high-quality and precious fiber is

manufactured from cotton linter, the short downy fiber enfolding cottonseeds, a

by-product of the cottonseed oil manufacturing process.

Since Bemberg™ is made from cotton

linter, it is biodegradable* and compostable

in soil and marine environment.

Closed

Loop manufacturing

The Bemberg™ fibres are produced

under the strict control of the chemical substances used in the manufacturing

process while introducing a closed-loop production system.

The Bemberg factory located in

Nobeoka, in southern Japan, deploys sophisticated technologies to produce the

fibers. The facility continuously works towards improving the quality of the

fibers and to preserve the natural environment.

Initiatives

for carbon neutrality

Asahi Kasei, the manufacturer of

Bemberg™, has initiated sincere initiatives on greenhouse gas (GHG) emissions.

It aims to reduce emissions by 30% or more by 2030 (from base year 2013) and to

become carbon neutral by 2050. To achieve these goals, Asahi Kasei is

conducting energy de-carbonation, emission reduction in the manufacturing

process, and production process innovation. Since its inception, Bemberg™ has

been using sustainable electric power from their own hydro-electric plants.

Indian

market

While Bemberg™ is preferred as

fashion material in many countries, in Indian market Bemberg™ is used in

conventional Sarees, Dupattas, Kurtis and Indo-western style garments as well

as menswear in the local production areas. Fabric made from Bemberg™ yarn are

imported in India since 1954, Bemberg™ is adored for its functionalities like

lustrous colors, unique smooth texture, breathability, and superior comfort.

Bemberg™, has been used even as

lining fabric of suits to impart attractive functionalities and features such

as drapability, high dyeability, beautiful luster and moisture-control. Indian

market demands such effective functionalities considering the climate and

fashion style. Bemberg™ is suitable to keep the wearers comfortable in Indian

summer which is very hot and humid. However, this specific functionality

waiting to gain popularity.

The fabric manufactured using

Bemberg™ yarn are becoming popular among Indian apparel brands not only because

of its functionalities like elegant luster and soft hand touch but also due to

its value as a plant-based material. This has attracted even more attention

recently with the growing demand for Vegan or cruelty free products.

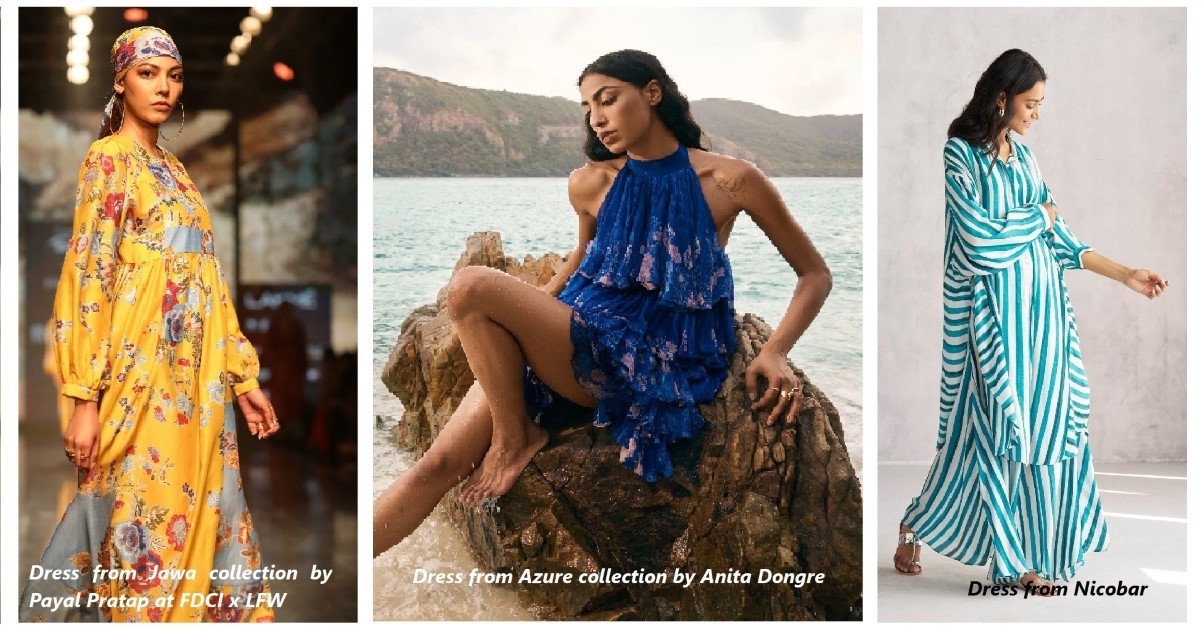

Bemberg™ has gained recognition in

India through the participations in FDCI X Lakmé Fashion Week while

collaborating with prominent Indian designers such as Hemang Agrawal and Payal

Pratap. Their collections focusing sustainability, Indian craftsmanship and

innovative creations with Bemberg™ yarn gained industry’s accolades. In

addition, few Indian brands are regularly creating items made with Bemberg™

yarn. For example, Nicobar known as modern and Indian craft items works with

Bemberg™ yarn. Asahi Kasei has recently released a first precious collaborated

collection called “Azure”: Nature-Inspired Aesthetics with sustainable

craftsmanship using Bemberg™ yarn with Anita Dongre.

The

path ahead

The demand for Bemberg™ is expected

to grow in India due to its sustainable, fashionable, comfortable features, and

plant-based origin. These product features match well with society’s needs and,

coupled with India’s economic growth, Bemberg™ could be a preferred raw

material. In addition, like other countries, the use of Bemberg™ in India is

expected to expand to categories like innerwear, activewear, and home textiles

due to its functionalities and soft hand feel.

Bemberg™ is a precious material made

from natural resources, and people can feel connected with its beauty even in

countries far from Japan. As we move towards a more sustainable future,

Bemberg™ is poised to play a significant role in the textile and fashion

industry.

* Bemberg™ biodegradability in soil

was verified by a testing organization, and its marine biodegradability is

certified by TÜV Austria.

(Asahi Kasei PR)

Bemberg™ is the brand name of cupro, a regenerated cellulosic fiber produced by Asahi Kasei in Japan since 1931 and exported to India for about 50 years. This high-quality and precious fiber is manufactured from cotton linter, the short downy fiber enfolding cottonseeds, a by-product of the cottonseed oil manufacturing process. Since Bemberg™ is made from cotton linter, it is biodegradable* and compostable in soil and marine environment.

If you wish to Subscribe to Textile Excellence Print Edition, kindly fill in the below form and we shall get back to you with details.