Carbon Fibre’s Circular Shift Gains Momentum with Scale‑up Data and Industrial Action

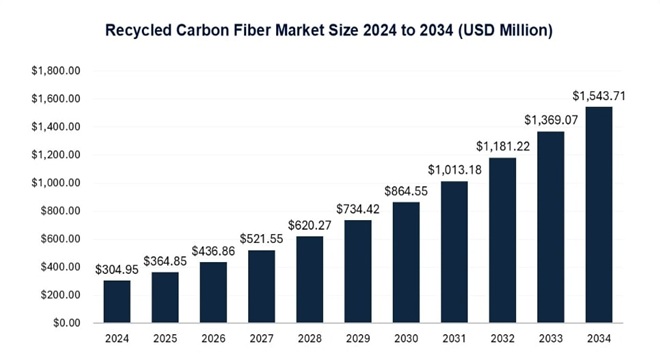

Global carbon fibre

recycling is expanding rapidly. Market size estimates vary, but conservative

figures peg it at US$ 197‑198 million in 2024, rising to US$ 382 million by

2030 at 13 % CAGR, while higher-end predictions project US$ 305 million in 2024

growing to USD 1.54 billion by 2034 at 17.6 % CAGR. Sharpest growth is expected

in Europe and Asia‑Pacific, where policy incentives and high demand from

automotive and aerospace are strongest.

Industry leaders such as

SGL Carbon, Toray, Teijin, ELG Carbon are actively scaling composite recycling

operations. Aerospace scrap leads sources at 43‑45 % share, while chopped

carbon fibre dominates product types at nearly 60 % in 2024. Pyrolysis remains

the most common recycling technique (70 % market share), with chemical

recycling soaring fastest (15–15.5 % CAGR).

Teijin has embedded

Life‑Cycle Assessment across its filament and recycling operations. It aims for

net‑zero emissions by 2050, deploying ISO 50001 and ISO 14001 systems and

reusing production heat for factory cooling. Teijin also produces biomass‑based

acrylonitrile carbon fibre and reclaims production scraps into pelletised

recycled fibre products.

Global carbon fibre reinforced

plastics (CFRP) waste is expected to reach about 20 kilotons annually by 2025,

as thousands of aircraft retire and components from wind turbine blades and

automotive composites enter the waste stream. Aviation consortia such as the

Aviation Circularity Consortium (ACC) estimate potential recovery of carbon

fibre from retired aircraft, while automakers and bike brands are beginning

partnerships with Teijin and Fujitsu to trace recycled material via blockchain

platforms.

India’s technical textiles

manufacturers should closely monitor recycled carbon’s emerging supply chains

and technology innovations. Domestic OEMs and composite yarn producers may

consider collaborations for mechanical and chemical recycling pilots and leverage

demand from mobility, sports and infrastructure sectors needing

high-performance circular materials. Manufacturers investing early in recycling

infrastructure, LCA practices and traceable supply chains can position India as

a sustainable fibre hub aligned with global circular economy mandates.

Circular carbon fibre

recycling is transitioning from niche pilot projects into a sizable industrial

economy. Material science innovation and scalable business models now offer a

pathway to reconcile high-performance composites with planetary boundaries and

long-term resource efficiency.

Global carbon fibre reinforced plastics (CFRP) waste is expected to reach about 20 kilotons annually by 2025, as thousands of aircraft retire and components from wind turbine blades and automotive composites enter the waste stream. Aviation consortia such as the Aviation Circularity Consortium (ACC) estimate potential recovery of carbon fibre from retired aircraft, while automakers and bike brands are beginning partnerships with Teijin and Fujitsu to trace recycled material via blockchain platforms.

If you wish to Subscribe to Textile Excellence Print Edition, kindly fill in the below form and we shall get back to you with details.