SPIDERweb - Way To Economic Spinning

Rieter's SPIDERweb Mill Control System has evolved as a key decision making tool for spinning mills. Latest generation of SPIDERweb is the only mill management system that collects, analyses and displays all relevant data in a spinning mill from fiber preparation to yarn stage covering all four spinning systems.

The control system rapidly identifies the deviations in production and assists timely intervention which increases the production and improves economic efficiency of a spinning mill. Also, regular monitoring reduces routine tests and ensures consistent quality. Monitoring systems began their move into the spinning mill with the collection of data and monitoring of the machines and operating processes. The next stage is the development of the precise control systems that can provide help in finding solutions to problems. With this integrated system, Rieter spinning mills have an edge and leads the way for economic spinning.

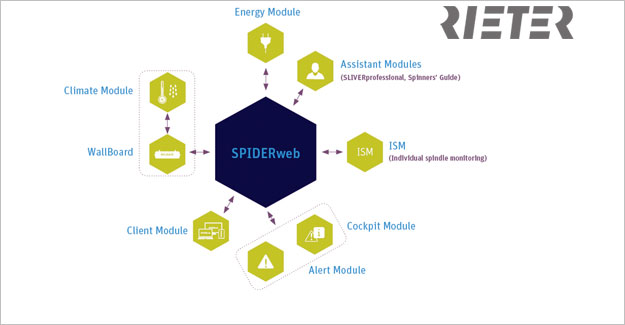

SPIDERweb: Modular Concept

The modular design of SPIDERweb allows any number of machines to be connected to it. SPIDERweb, the basic module is today well-known and proven system. It forms the foundation for connecting further hardware and software modules. SPIDERweb has been continually modernised and further developed for more than 20 years.

Over 10,000 machines in nearly 50 countries are already connected. Tried and tested modules such as the WallBoard and the individual spindle monitoring ISM are integral parts of the system.

Alert and Cockpit Modules Complement Each Other

The SPIDERweb system and modules are configurable for individual requirements. The plant manager can define the parameters and transgressions he wants to be reported to him. Should a value be exceeded or not reached, a short notification will be sent to his smartphone. And, therefore, allows him to be at complete control of the spinning mill and requires minimal inspection visits. Similarly, the quality manager sets the alarms as he considers appropriate. Quality rejection can be reduced due to quicker response times. Quick monitoring after receipt of an alarm or a faster overview at the end of a shift - the Cockpit Module provides a view of the most important spinning mill data from every location.

Climate Module Makes Connections

It is a well-known fact that the climatic conditions in a spinning mill exert influence on the running behaviour and the quality it produces. With the help of the temperature and humidity sensors, current values are constantly shown on the WallBoards and are simultaneously transmitted to SPIDERweb. Efficiency reductions without any detectable reason gain transparency.

Assistant Module - The Efficient Helper

SLIVERprofessional allows easy problem management of periodical faults on Rieter draw frames. The fault search is simplified and accelerated. Indication regarding the cause of the fault is visually displayed. Long fault diagnostics are therefore a thing of the past. Setting recommendations for each material and sliver count help right from the start to take the right path.

Rieter Spinners' Guide Belongs To The Assistant Module

The integrated Spinners' Guide helps and guides the management along the right path when such need arises (say for example, to spin yarn for a new application or while expanding the product range).

It provides process recommendations from the bale processing to yarn manufacture, detailed spinning recipes for all spinning technologies are readable, based on the textile application. Filter functions help to find the right recipe according to application, material or yarn count. The guide shows which components are needed and how they are used.

Textile Excellence

If you wish to Subscribe to Textile Excellence Print Edition, kindly fill in the below form and we shall get back to you with details.