Schoch Weaves Blueprint To Cover More Accessories

Nearly a century-old Italian company manufacturing world famous reeds for looms made a blueprint in 2009 to lay the foundation for an Indian facility… and Schoch Reeds India was born! In just a matter of nine years, the dream matured into a fully-grown company in Kolhapur, supplying reeds of same, unfailing quality to not only Indian looms but also to some major textile producing countries. Since 2009, there was no looking back for Schoch Reeds in India. Over the years, the company has been manufacturing quality precision reeds.

During recent talk, Kuldeep Pareek, who recently took over the helm as General Manager – Sales & Marketing of Schoch Reeds India, discussed the company’s plans to introduce three new products, apart from supplying reeds. At ITMA, Schoch Reeds plans to launch drop wires, heald frames and heald wires. “We, at Schoch Reeds now plan to cover the entire spectrum of accessories for the weaving segment,” proudly says Pareek.

3 new products for ITMA

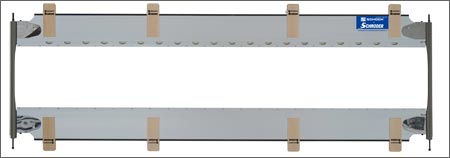

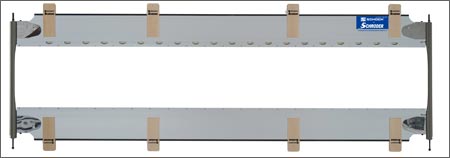

Heald frames: The heald frames are made with high strength anodised aluminum alloy and with stainless steel rods. Available for all type of shuttleless loom and carbon fibre reinforcement available for high speed looms. Lateral supports are designed for higher loom speeds and suitable for all major loom manufacturers. Also custom-made solutions are available.

He adds, “We will supply all types of heald frames from the existing design available in the market. For manufacturing heald frames, Schoch is in the process to set up heald frame manufacturing facility in India. Assembling and repairing facility will be available from July onwards.”

For heald frames, Schoch Reeds has collaborated with Schroeder, who is in this business since long time. “So, we will provide heald frames in name of Schoch & Schroder,” said Pareek.

Heald wires

He adds, “We will supply all types of heald frames from the existing design available in the market. For manufacturing heald frames, Schoch is in the process to set up heald frame manufacturing facility in India. Assembling and repairing facility will be available from July onwards.”

For heald frames, Schoch Reeds has collaborated with Schroeder, who is in this business since long time. “So, we will provide heald frames in name of Schoch & Schroder,” said Pareek.

Heald wires

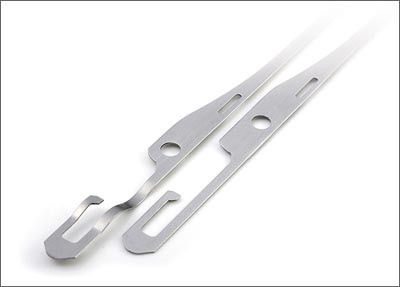

Manufacturing of heald wires require more precision. The heald wires are available in J - C shape. Also custom-made solutions are available. It is suitable for all present automatic drawing-in machines, and are exclusively made with tempered stainless steel quality SUS420J2 for the demanding weaving industry.

On manufacturing heald wires, Pareek says, “We are currently starting with manufacturing one type of heald wires, and may be in another year or so, we will come out with the all type version.”

Drop wires

The droppers are manufactured with a new and innovative technology. It has an extremely smooth finishing and is ideal for delicate yarns. It will be suitable for all drawing-in machines, and exclusively manufactured with tempered stainless steel quality SUS420J2. “We have already started manufacturing drop wires in India. Custom-made solutions can be manufactured on demand,” says Pareek.

Manufacturing of heald wires require more precision. The heald wires are available in J - C shape. Also custom-made solutions are available. It is suitable for all present automatic drawing-in machines, and are exclusively made with tempered stainless steel quality SUS420J2 for the demanding weaving industry.

On manufacturing heald wires, Pareek says, “We are currently starting with manufacturing one type of heald wires, and may be in another year or so, we will come out with the all type version.”

Drop wires

The droppers are manufactured with a new and innovative technology. It has an extremely smooth finishing and is ideal for delicate yarns. It will be suitable for all drawing-in machines, and exclusively manufactured with tempered stainless steel quality SUS420J2. “We have already started manufacturing drop wires in India. Custom-made solutions can be manufactured on demand,” says Pareek.

“We will have the advantage of manufacturing reeds in-house in Kolhapur itself. The new products will focus on better delivery time, and on providing quality products within India,” adds Pareek.

On USPs of these new products, Pareek says: “The main USP of these products will be the delivery time and the raw materials used. We are using quality-graded steel, which is imported. The steel used is very hard. For these products, finishing is very necessary. So we are using the best technology of finishing.”

The revolutionary eReed concept

eReeds are energy-saving reeds that were launched a few years back. The textile mills in India have very high power cost. In many states, there is severe power crisis hence mills are forced to invest in captive power, which has further increased costs. It is in this context that Schoch Reeds has launched a new range of reeds, which offer significant savings in energy cost. Pareek says, “We also introduced eReed concept, which is doing really well in India. eReeds are basically energy-saving reeds. The concept has already become popular, and there are customers who want only eReeds.”

Staying ahead of the competition

On tackling the competition from Chinese and Indian markets, Pareek says: “The competition will be always there – whether from China or from India. I am not saying that their products are of lesser quality. But at Schoch Reeds, our main focus is on providing high quality products to the customers. We will be manufacturing these products in-house. In that way, we can have the control on quality. We have set up checkpoints after each process in our production following the TQM model to control quality. We will strengthen our sales force. By that way we can fight competition.”

“We maintain our quality standards as per the ISO norms, and have received the latest ISO certificate for the same. It is the mark on our quality parameters,” said Pareek. Schoch Reeds India received the ISO 9001 : 2015 certification from TUV NORD CERT on March 18, 2019.

“We will have the advantage of manufacturing reeds in-house in Kolhapur itself. The new products will focus on better delivery time, and on providing quality products within India,” adds Pareek.

On USPs of these new products, Pareek says: “The main USP of these products will be the delivery time and the raw materials used. We are using quality-graded steel, which is imported. The steel used is very hard. For these products, finishing is very necessary. So we are using the best technology of finishing.”

The revolutionary eReed concept

eReeds are energy-saving reeds that were launched a few years back. The textile mills in India have very high power cost. In many states, there is severe power crisis hence mills are forced to invest in captive power, which has further increased costs. It is in this context that Schoch Reeds has launched a new range of reeds, which offer significant savings in energy cost. Pareek says, “We also introduced eReed concept, which is doing really well in India. eReeds are basically energy-saving reeds. The concept has already become popular, and there are customers who want only eReeds.”

Staying ahead of the competition

On tackling the competition from Chinese and Indian markets, Pareek says: “The competition will be always there – whether from China or from India. I am not saying that their products are of lesser quality. But at Schoch Reeds, our main focus is on providing high quality products to the customers. We will be manufacturing these products in-house. In that way, we can have the control on quality. We have set up checkpoints after each process in our production following the TQM model to control quality. We will strengthen our sales force. By that way we can fight competition.”

“We maintain our quality standards as per the ISO norms, and have received the latest ISO certificate for the same. It is the mark on our quality parameters,” said Pareek. Schoch Reeds India received the ISO 9001 : 2015 certification from TUV NORD CERT on March 18, 2019.

Textile Excellence

If you wish to Subscribe to Textile Excellence Print Edition, kindly fill in the below form and we shall get back to you with details.