Arvind Ltd To Use 100% Reclaimed Water By End Of 2020

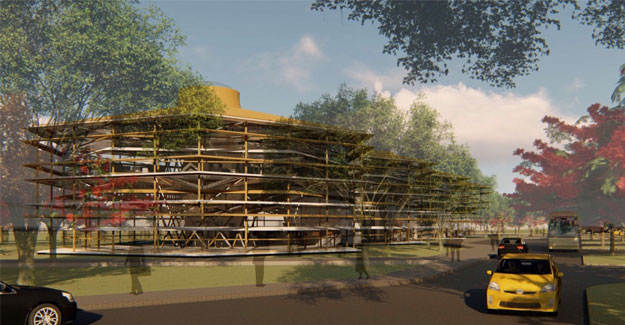

Gap Inc. and Arvind Limited have joined hands to reduce apparel industry's water use and drive water-saving innovations. Global apparel retailer Gap Inc. (NYSE: GPS) has announced a new partnership with its longtime sourcing and franchise partner in India, Arvind Limited, to drive industry-leading solutions that address global water scarcity. The apparel industry is one of the most intensive users of water in the world and, in India, 54% of the population faces high to extremely high water risk. The two companies will open a new innovation centre to promote the adoption of proven techniques and technology that reduce water use by the textile manufacturing industry. Further, Arvind and Gap Inc. are also investing in a new water treatment facility that will eliminate the use of fresh water at Arvind’s denim mill in Ahmedabad, India. The facility will save three billion litres of fresh water by the end of 2020 and preserve the local community’s vital freshwater resources. As water becomes increasingly scarce due to climate change and growing human needs, the apparel industry is facing pressure to reduce its demand for fresh water. When it opens in 2020, the new centre will be an innovation hub for apparel companies, manufacturing suppliers and vendors, sustainability experts, academics, and other environmental stakeholders to advance and scale water stewardship across the apparel sector. The 18,000-square foot space will feature: installations that showcase water management best practices and recycling technologies; a library; lab space to develop water management solutions as well as classroom training and conference space. Once completed, the centre will generate scalable solutions that can be replicated at other mills and laundries. Today, Arvind’s denim mill in Ahmedabad – the first mill in India to manufacture denim – consumes eight million litres of fresh water per day. Once constructed, the new water treatment facility will replace 100% of its freshwater use with reclaimed water. Specifically, the new facility will use Membrane Bio Reactor (MBR) technology to treat domestic wastewater drawn from the surrounding community without the use of chemicals in the treatment process, resulting in a cleaner, more sustainable process. The facility is currently under construction and is expected to be commissioned by September. Beyond eliminating the use of fresh water at the denim mill, the facility will also reduce business risk for Arvind, Gap Inc. and the other brands that source from the mill due to local water scarcity challenges. This effort brings together two major industry players. Arvind’s textiles manufacturing in India dates back to 1931 while Gap Inc.’s global supply chain operates across more than 30 sourcing countries. “The world is facing a water crisis, and Gap Inc. is committed to finding meaningful, scalable ways to reduce our water use. Traditionally, manufacturing apparel has been a water intensive, water wasting process,” said Art Peck, president and chief executive officer, Gap Inc. “This partnership with Arvind Limited is an important step towards changing that, and we look forward to collaborating across the industry to accelerate the transformation to more efficient and sustainable water use practices.” “Arvind is committed to eliminating the use of fresh water from its textile production operations. We have made significant investments in water reduction and recycling activities over the past two decades,” said Punit Lalbhai, Executive Director, Arvind Limited. “Gap Inc. is our key strategic customer and this partnership is valuable for us to achieve our water goals collectively. The partnership will also help in expanding scope of water savings to the broader industry through Center of Excellence.” In 2018, Gap Inc. unveiled a new sustainable manufacturing goal to conserve a total of 10 billion litres of water by the end of 2020. Through product design innovation and partnering with fabric mills and laundries, the company has saved more than 5.7 billion litres of water. And because cotton is an extremely water-intensive fibre, Gap Inc. began sourcing cotton from the Better Cotton Initiative (BCI) in 2016 to support the improvement of cotton farming practices globally. The company recently announced it will source all cotton for its family of brands from sustainable sources by 2025. Helping communities improve access to clean water and sanitation is another core focus. In 2017, Gap Inc. and the US Agency for International Development (USAID) launched the Women + Water Alliance in India, a partnership to improve and sustain the health and well-being of women and communities touched by the apparel industry. Arvind’s sustainability strategy, Fundamentally Right, revolves around an input management approach with the goal to make all key inputs 100% sustainable. Water is one key input, and Arvind plans to eliminate the use of fresh water from its textile production by the end of 2020. Currently, 65% of the company’s water use is from recycled sources. Once completed, the new treatment facility is expected to help the company achieve 90% from recycled sources. Arvind also has the largest sustainable cotton farm operation in India for a textile mill.

Textile Excellence

If you wish to Subscribe to Textile Excellence Print Edition, kindly fill in the below form and we shall get back to you with details.