Rieter: Maximum Flexibility And Future-Oriented Automation

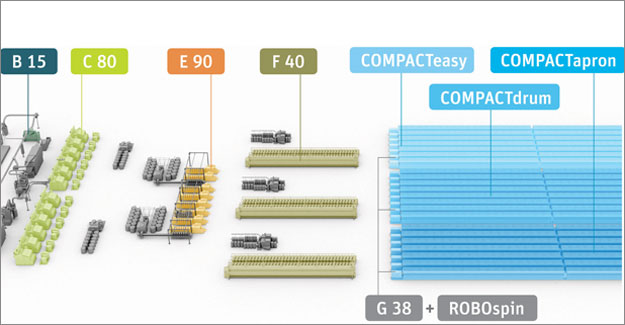

The right compacting system for everyone Every customer has its own specific requirements for ensuring the success of its spinning mill. As a system supplier with many years of experience, Rieter offers the broadest portfolio on the market, which is continually updated to offer even more flexibility. In end spinning, the COMPACT family opens up new possibilities for the compacting process. The three new compacting devices COMPACTeasy, COMPACTdrum and COMPACTapron are easy to install and remove, enabling simple switching between ring yarn and compact yarn. The devices fulfill a range of different customer requirements: very high yarn tenacity, reduction in hairiness, or an investment requirement that is as low as possible. The devices are suitable for use with all Rieter ring spinning machines. For customers who want to produce further high-quality special yarns alongside compact yarn, the G 38 is the ideal solution. Thanks to the integrated VARIOspin system for slub yarns, the customer can change between standard and slub yarns simply at the touch of a button. The Rieter compacting system is therefore suitable for all yarn types, raw materials, and yarn counts. The VARIOline already offered the VARIOset function for rapid adjustment of blowroom machinery according to the properties of the raw material. This function is also available with the new high-productivity UNIclean B 15. The future of spinning ROBOspin is the first reliable piecing robot in ring spinning. It automates the piecing process - from finding the yarn, through threading into the traveler, to piecing the yarn. Ring spinning becomes even more attractive. The new fully automated roving frame F 40 with the shortest doffing time on the market also ensures rapid bobbin change and high efficiency. With the comber, the most frequently used machine settings have been greatly simplified. Some settings that previously required mechanical adjustment can now be easily changed on the operating unit. In addition the proven lap transport system SERVOlap and the automated lap change and batt piecing system ROBOlap enable further autonomy. Rieter is now offering its customers a new concept featuring cans with a diameter of 1?200?mm as an alternative for the spinning preparation. This increases the machine efficiency while also reducing personnel costs and waste. Fewer sliver pierces also increase the yarn quality. With the use of Rieter ESSENTIAL, the ring spinning and compact-spinning process are optimally supported too.

Textile Excellence

If you wish to Subscribe to Textile Excellence Print Edition, kindly fill in the below form and we shall get back to you with details.