Rieter SB-D 50 Ensures Easy Processing Of Dusty Linen-Viscose Blend

The highly efficient suction system of the draw frame SB-D 50 enables Chaohu Youngor to process dusty material like linen fibres. The single-head draw frame without autoleveler produces with a delivery speed of 800 m/min at high efficiency with a blend of linen and viscose.

To increase productivity, Chaohu Youngor Color Spinning Technology Co Ltd, which is located in Anhui Province, China, built a new spinning mill with 57 000 spindles in 2021. The company processes cotton, linen, viscose, and their blends. To ensure it could maintain the demands on yarn quality well into the future, it bought six pairs of draw frames SB-D 50 and RSB-D 50 for the new mill.

China is the largest producer of linen fabrics. The popularity of linen has increased in recent years, especially for clothing. Linen is very breathable and dries faster than cotton, making it comfortable to wear even in hot weather. However, a major challenge for spinners is that linen fibres have a high trash content and tend to generate wood dust during processing, especially on the first draw frame passage. This can lead to deposits on machine parts, particularly at higher speeds. These deposits cause tedious cleaning work for the operator in the drafting and coiling area and, if delayed, can lower machine performance.

Draw frame SB-D 50 with efficient suction system

The single-head draw frame SB-D 50 without autoleveler offers the greatest flexibility. It is designed for cotton and man-made fibres but is also perfectly suited to process special fibres like linen with high productivity. For easy processing of dirty and dusty material, the SB-D 50 is equipped with a highly efficient suction system. The cleaning lips are lifted regularly so that trash accumulations end up directly in the suction. The automatic filter cleaning system keeps the filter screen clean with the help of a wiper. The operator can set the suction intensity easily and quickly on the machine display. Four suction slots in the infeed of the drafting unit enable a 24-hour operation. The efficient suction system at the pre-draw frame reduces dust during coiling and keeps the production efficiency in the subsequent processes at a high level.

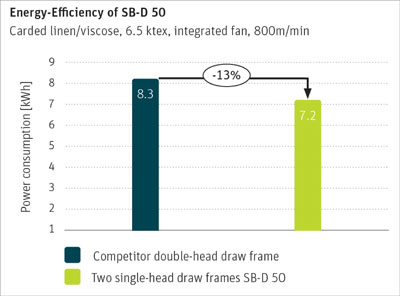

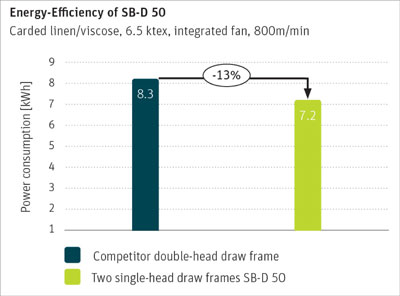

High productivity, easy handling and 13% energy savings

“I am very satisfied with the operation and productivity of the SB-D 50 at high speed. The

[caption id="attachment_23974" align="alignleft" width="400"] The customer saves 13% energy, thanks to the innovative machine concept.[/caption]

draw frame runs smoothly and trouble-free with a blend of linen and viscose (55/45%) at 800 m/min”, states Chen Lianguang, Quality Manager at Chaohu Youngor. The easy accessibility for maintenance work and the central lubrication point also make working with the SB-D 50 convenient for the operator. Six machines can be easily handled by one operator. In addition, the workload at the next draw frame and at the roving frame is reduced due to fewer stoppages and sliver breaks. The excellent operation of the SB-D 50 thus ensures consistent sliver quality with high productivity and best yarn quality in downstream processes. Thanks to the patented drive concept ECOrized with fewer drive elements, the SB-D 50 saves energy even at higher delivery speeds. The frequency-controlled drive for the suction and the individual drive for the coiler are unique. As a result, Chaohu Youngor benefits from 13% energy savings compared to the competitor machine.

The customer saves 13% energy, thanks to the innovative machine concept.[/caption]

draw frame runs smoothly and trouble-free with a blend of linen and viscose (55/45%) at 800 m/min”, states Chen Lianguang, Quality Manager at Chaohu Youngor. The easy accessibility for maintenance work and the central lubrication point also make working with the SB-D 50 convenient for the operator. Six machines can be easily handled by one operator. In addition, the workload at the next draw frame and at the roving frame is reduced due to fewer stoppages and sliver breaks. The excellent operation of the SB-D 50 thus ensures consistent sliver quality with high productivity and best yarn quality in downstream processes. Thanks to the patented drive concept ECOrized with fewer drive elements, the SB-D 50 saves energy even at higher delivery speeds. The frequency-controlled drive for the suction and the individual drive for the coiler are unique. As a result, Chaohu Youngor benefits from 13% energy savings compared to the competitor machine.

Textile Excellence

If you wish to Subscribe to Textile Excellence Print Edition, kindly fill in the below form and we shall get back to you with details.