Being Close To The Customer Is Most Rewarding

'Change before you have to’ seems to be a well-entrenched mantra at Lakshmi Machine Works Limited. Sanjay Jayavarthanavelu, Chairman & Managing Director of LMW, believes in being relevant and the partner of choice to the global textile industry, in a business environment witnessing unprecedented changes. Let’s read here about Mr Sanjay Jayavarthanavelu’s aspirations, endeavours, principles and vision.’

As a kid, do you remember how most of us loved to visit our father’s workplace? And if your father owned the business, you could do more there than merely visit his office. Well, there was this young teenage boy who would never miss an opportunity to spend time at his father's workplace. While his friends would make plans for the holidays, he could not keep himself away from this fascinating company that created machines. "So this was a very nice introduction that I had to Lakshmi Machine Works at the early age of 15. I started as an apprentice and got to know the works, the trades, and different parts and aspects of the business early in life. I can say confidently that textiles and machines are in my blood,” reminisces Sanjay Jayavarthanavelu, CMD, LMW. Eventually, after his formal education, he joined the board of the Company and assumed the role of a member of the board. Over the years, his passion and love for the business kept growing.” "I had to finally take over the Company's reins after my father's passing. And I had to fill in my father’s and grandfather's really big shoes. Fortunately, by then, they had built a strong foundation for LMW, so it was relatively easy for me and my team to stick to that proven path and move along."

‘The Customer's Perception Is Your Reality'

So, what inspired him in those early years? "For me, then and now, understanding my customer and customer's customer – is an essential and critical job. My customers are my inspiration. Our customer's dreams are our dreams "So, soon after I joined the business, I started to travel and meet the customers. The Indian textile industry is a vital part of the global textile chain, and Indian textile companies had many aspirations. And we took on the responsibility of giving them the best technological solutions, so they could make their mark in the global textile value chain.

‘Innovation is the ability to see change as an opportunity'

LMW is a striking example of a company that has succeeded by understanding the market and the environment, anticipating changes, and being ready with the right solutions when the customers finally realise the need for them.

Late Cav. G.K. Devarajulu, Founder, Lakshmi Machine Works Ltd. with President of India, Zail Singh, at Rashtrapathi Bhawan, New Delhi.

Late Cav. G.K. Devarajulu, Founder, Lakshmi Machine Works Ltd. with President of India, Zail Singh, at Rashtrapathi Bhawan, New Delhi.

“In the sixties and seventies, many Indian manufacturing companies depended almost entirely on foreign technology. LMW's initial journey was no different. However, our technology pipeline dried up early, and this challenge became an opportunity as my father ensured that we built a solid R&D team in-house. LMW's vision was clear – innovation is the only way to success. We commenced working closely with customers, developing contemporary products, and ensuring world-class technology, solutions, and service. This effort strengthened our brand and gave confidence to the industry”.

Sanjay Jayavarthanavelu makes it sound easy but was it so?

"Of course not. It required a solid commitment to the vision, investments, and a clear, focused mindset. It was an exciting journey, and we expect it to continue as we go ahead. It opened our minds to new materials, innovation, processes, hardware and software development, the development of people, understanding the world of international and local patents, and coming up with new solutions. And that's just one part of it.” "Going ahead, we are moving up the chain and focusing on how to meet customers' future expectations and requirements. Everything is changing; the environment, the rules and regulations, the world, the customers, and our customer's customer - the retail buyer. Everyone is facing new challenges, creating the need for newer solutions. So the next step is to gauge and anticipate changes and meet expectations ahead of time."

"Of course not. It required a solid commitment to the vision, investments, and a clear, focused mindset. It was an exciting journey, and we expect it to continue as we go ahead. It opened our minds to new materials, innovation, processes, hardware and software development, the development of people, understanding the world of international and local patents, and coming up with new solutions. And that's just one part of it.” "Going ahead, we are moving up the chain and focusing on how to meet customers' future expectations and requirements. Everything is changing; the environment, the rules and regulations, the world, the customers, and our customer's customer - the retail buyer. Everyone is facing new challenges, creating the need for newer solutions. So the next step is to gauge and anticipate changes and meet expectations ahead of time."

Changing the ‘foreign machines are better’ mindset

‘European, Japanese technologies are better than Indian technology' is a common mindset among customers worldwide. In every field, there are Indian gems that have proved otherwise. In the textile engineering industry, LMW is one such gem.

“Access to technology was a significant obstacle for LMW. There are two types of technology - one that you develop within the organisation, and second is where you have to access from other industries and institutions. The second type of technology was and is a big challenge for varied reasons". With sheer determination and unflinching investment, LMW overcame this obstacle.

"Today, we work with many institutions and individuals and have access to technology. It took us time, and we made mistakes, but in innovation and design, there is no way to succeed if you don't make mistakes. That was a big learning for us."

And how did LMW develop technology in-house?

"We did a good job digesting the technology we bought and making innovation a part of our process. Now when I say innovation, it does not mean always creating something very new, it can be something familiar. We have been able to deliver continuous improvement of small things to customers. As I said, we listen to our customers. The proof of our success is our satisfied customers who appreciate that we can deliver as good and even better solutions than our competitors offer." LMW has focussed just as much on establishing its brand presence worldwide as it has on ensuring the best solutions to the global industry. "LMW has been participating in ITMA in Europe since the first show. This helped gain recognition for LMW very early in the global arena. So today, when we enter new geographies, the brand and the values the brand and the Company represent are already known. After that, it's like servicing any other customer – fulfilling their tech needs and ensuring the best service and support. We sell equipment, so we are with the customer at least till the lifecycle of the machine." How far ahead LMW is in the game is also evident from its various that are limited not just to textiles, but span aerospace, defence, and satellite technologies too. "Very few of our competitors have that kind of width of experience in terms of working with different materials and requirements. It's a trickle-down effect where we can ensure precision, accurate tolerances and quality, imbibed across the entire organisation. And that really will put us in good stead ahead."

Follow the leader

Why has the Indian textile technology industry not reached the level of success that LMW and others have scaled? "Today, for the textile industry to grow well, I believe, and all my customers believe, you need to have an Indian-owned OEM/technology company to back you up. This is what is happening in the rest of the world. So, if there is only one such company in the whole chain of textiles, that would be a concern over the years. We need to see more Indian companies developing world class weaving, knitting, and processing solutions - we need indigenous suppliers. There is immense scope for young entrepreneurs to come into this area." The Indian textile engineering industry understands the vast potential that is available globally but remains hesitant. "We had technology coming in from our collaborators, and it was smooth sailing till then. But we started building our technology when the signs came that this pipeline would dry up. You can see similar examples in other similar industries like automotive. Companies that developed their technology are doing far better than those that look for technology from outside. "Competition will always be there, from domestic and international players. Competition keeps us awake. If there is no competition, then complacency will creep in, and eventually, someone else will come up. We have to face it and provide differentiated products."

Delivering not just a product, but an experience

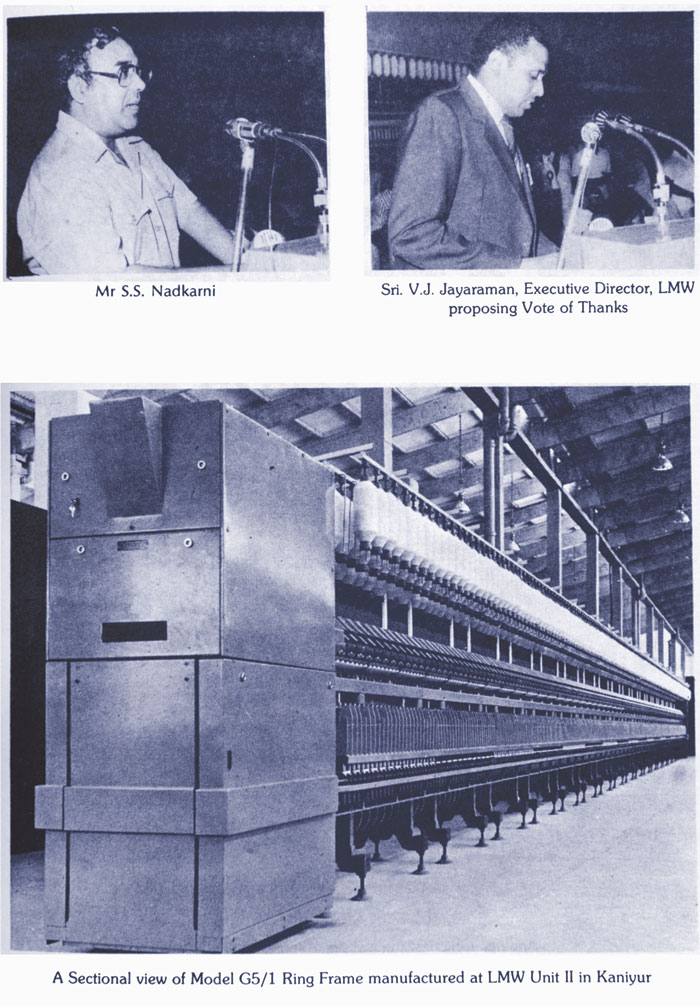

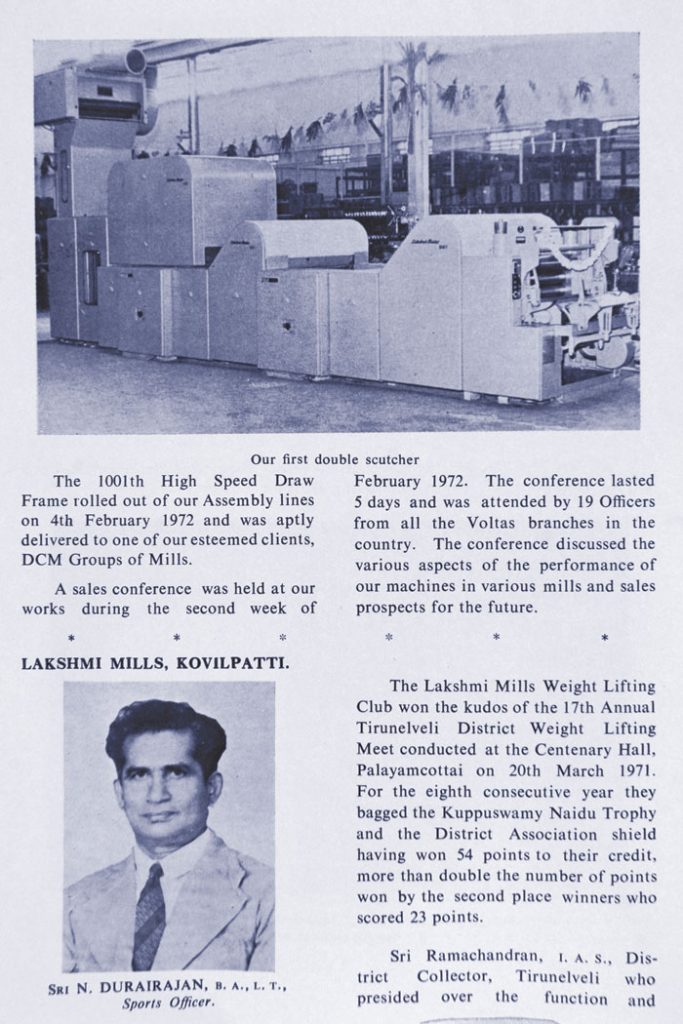

LMW, over the years, has developed many fascinating products and solutions. And Sanjay Jayavarthanavelu has some clear favourites. "Volume-wise, the Company is very proud of our ring frames. Today, we are among the largest producers of ring frames globally. So we have reached scale here. Value-wise and technology wise, our carding and combing machines are very sophisticated machinery doing quite well. And now our foray into the next areas of technology – cone winding and jet spinning - will perhaps be even dearer to us going forward because these are completely ground-breaking technologies from LMW. So far, we were just in spinning, and now we are getting into these two areas too." "And what's even more fascinating is how some of our clients have used our machines to make amazing high-value yarns. In the early 1990s, 4-5 customers in India started developing specialised yarns with our machines. This resulted from tremendous effort and innovative processes from our customers' side to work with different materials, fibres and processes. And now this is a trend, with a wider variety of customers who no longer make simple commodity yarn, but can create speciality yarns." "We are proud that our machines can be used in a versatile manner. And now the trend is towards more versatile, very different fibres. So it will be an exciting next ten years to see the kind of materials which will go through our machines."

Great times ahead for the textile engineering industry

"The Indian textile engineering industry will have an excellent future only because India will have a great future. Demographically, we are the youngest consumers, the largest consumers, and the youngest and largest work pool, so demographic dividend will play well for us.” "We are the second largest textile industry in the world, with great opportunities moving forward – new fibres, technology, automation, etc., will take our textile business to a completely new and different level. And the textile engineering business will bear the fruit."

The Indian textile engineering industry will have an excellent future because India has a great future. Demographically, we are the youngest consumers, the largest consumers, and the youngest and largest work pool, so demographic dividend will play well for us. We are the second largest textile industry in the world, with great opportunities moving forward – new fibres, technology, automation, etc., will take our textile business to a completely new and different level. And the textile engineering business will bear the fruit.

If you wish to Subscribe to Textile Excellence Print Edition, kindly fill in the below form and we shall get back to you with details.