Forget 3D Printing: Cornell Is 3D Knitting With Its New Machine

If you find 3D printers to be just a little too coldly

futuristic, this contraption might be more to your liking. Scientists from

Cornell University have created a machine that knits solid 3D objects out of

nice old-timey conventional yarn.

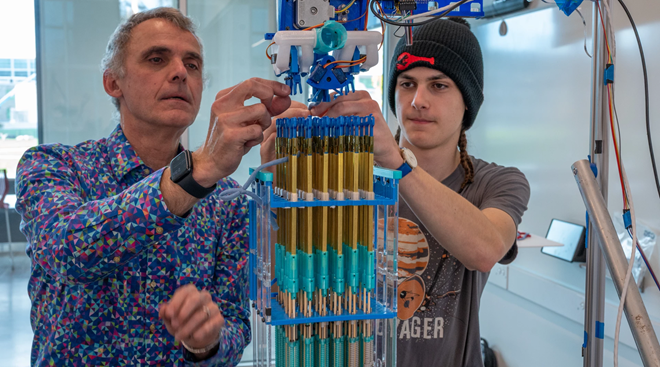

The prototype device is made mainly of 3D-printed

components, and incorporates a bed of knitting needles arranged in a 6 x 6

block. A motorised knitting head dispenses yarn to any of those needles in

sequence, as determined by a program on a computer that's controlling it.

Each of the needles in turn consists of a 3D-printed

symmetrical double hook connected to a brass support tube. Because the front

and rear sections of the hook move independently, it's possible for the device

to either knit or purl, depending on which section of the hook picks up the

first loop of yarn.

The machine is still relatively slow at this point, and

prone to errors such as dropping loops; plus so far it's limited to creating

simple objects such as wrist warmers, pyramids and boxes. That said, its

functionality should improve considerably once the technology is scaled up,

which would partially involve adding more needles to the knitting block.

Possible future applications of the device include the

production of three-dimensional scaffolding-like structures used to support the

growth of artificial ligaments or veins. And by knitting such structures

instead of printing them, it will be possible to precisely control their

thickness and stiffness.

"We establish that not only can it be done, but because

of the way we attach the stitch, it will give us access to a lot of flexibility

about how we control the material," says the lead scientist, Prof.

François Guimbretière. "The expressiveness is very similar to a 3D

printer."

A paper on the study was presented in September at the ACM

Symposium on User Interface Software and Technology in Busan, Korea.

And no, this isn't the first time we've heard about

3D-knitted objects.

Carnegie Mellon University, which collaborated with Cornell

on its device, has previously developed software that transforms existing

knitting machines into 3D printers, built a dedicated solid-knitting machine,

and created robo-knit furniture that transforms from flat to three-dimensional

shapes with one pull.

Possible future applications of the device include the production of three-dimensional scaffolding-like structures used to support the growth of artificial ligaments or veins. And by knitting such structures instead of printing them, it will be possible to precisely control their thickness and stiffness.

If you wish to Subscribe to Textile Excellence Print Edition, kindly fill in the below form and we shall get back to you with details.