How Best To Recycle Europe’s Fast Fashion Waste? Grow Mushrooms On It, Say Researchers

Most clothing and home textile waste currently still goes

unsorted, whilst fashion is driving significant increases in unwanted goods. EU

Member States must separate textile waste under the Waste Framework Directive,

but problems remain despite this legislation. Options include carrying out

extensive sorting and separation, or recycling mixed textiles into new

products. However, there is a lack of commercially viable technologies for use

in mixed textile recycling.

A review of 27 research papers has identified the following

products as offering the most potential for re-using this waste:

-

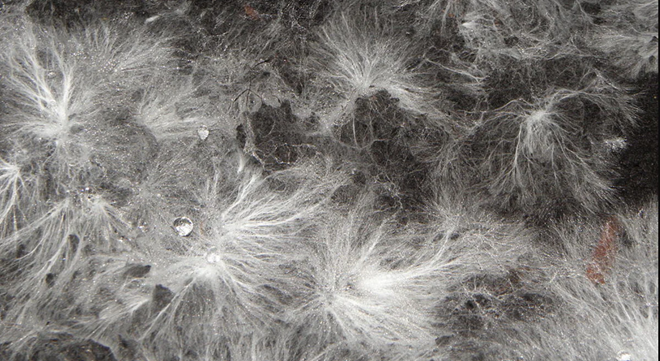

Fungi-based (mycelium) composite for thermal

insulation: This can be used e.g. to increase home energy efficiency as a green

building material, or to improve thermal performance in industrial processes

and mechanical systems.

-

Bio-oil and terephthalic acid (TPA): These

substances are used in chemical production to create plastics, resins,

composites, and paints, with TPA being a precursor to polyethylene

terephthalate (PET; a polyester widely used in clothing, packaging, and manufacturing).

-

Textile-reinforced composite for use in

construction: For example, to retrofit existing buildings, or used in place of

traditional steel-reinforced concrete blocks as a stiffer, more lightweight,

more durable building material;

-

Cotton and nylon fibres, spandex monomers

(molecules for spandex production) and bis(2-hydroxyethyl) terephthalate (BHET;

a compound that can produce polymers for numerous applications such as resins,

foams, and bioplastics). These fibres could also be recycled back into

textiles, closing the recycling loop.

The researchers calculated how close each use would be to an

ideal solution, using four criteria - environmental, economic, technical,

social - and rated each option. They found fungal-based insulation material had

the greatest future development potential. This can be achieved by growing

Pleurotus pulmonarius, a type of oyster mushroom, on a mixture of

agro-industrial waste and recycled ground textiles.

This option came out on top because the process to produce

the material is well-researched and simple, it has both a high economic

viability and market potential, and, as it can be produced from a wide range of

wastes and by-products, it has considerable possible environmental advantages.

Insulation grown on a mixed-textile substrate using mycelium offers a potential

solution as part of the Strategy for a Sustainable Built Environment, which

promotes the use of novel, low-carbon and circular materials. However, the

researchers found the composite material analysed in the work to have notably

poorer (higher) thermal conductivity than existing alternatives such as

polystyrene, and so this should be an area of focus for future research to

optimise the product and explore its applications.

They found the second-best option to be textile-reinforced

composite, followed by BHET, spandex, cotton and nylon, and finally bio-oil and

TPA. The latter two products were rated highly for technical readiness and

market competitiveness, but lower for environmental impact (due to the high

cradle-to-gate Global Warming Potential (GWP) of the processes required to make

them, which is up to 3 times that of producing crude oil). The

textile-reinforced composite showed good technical performance and reasonable environmental

and social impacts, according to the analysis, but poor economic performance.

With separate textile waste collection expanding across

Europe, this research helps policymakers and industry understand where to focus

investment. While mycelium-based solutions look promising, further testing and

pilot projects are still needed before large-scale adoption.

The researchers calculated how close each use would be to an ideal solution, using four criteria - environmental, economic, technical, social - and rated each option. They found fungal-based insulation material had the greatest future development potential. This can be achieved by growing Pleurotus pulmonarius, a type of oyster mushroom, on a mixture of agro-industrial waste and recycled ground textiles.

If you wish to Subscribe to Textile Excellence Print Edition, kindly fill in the below form and we shall get back to you with details.