Birla Cellulose And Circulose Join Forces To Scale Textile Recycling And Circular Fibres

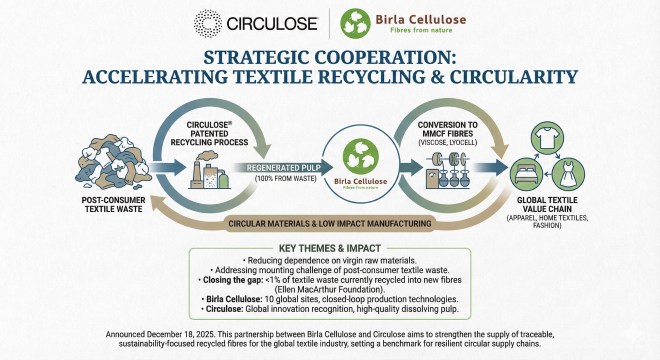

Birla Cellulose and Circulose have entered into a strategic cooperation agreement aimed at accelerating textile recycling and strengthening the supply of recycled fibres for the global textile value chain. The agreement was announced on December 18, 2025 and reflects a growing industry shift toward circular materials and low impact manufacturing.

Under the cooperation framework, Circulose will supply regenerated pulp produced entirely from textile waste to Birla Cellulose. The pulp will be converted into man made cellulosic fibres and delivered to downstream partners across apparel, home textiles, and fashion segments. Industry experts view the move as a critical step toward reducing dependence on virgin raw materials while addressing the mounting challenge of post consumer textile waste.

Birla Cellulose, the cellulosic fibres business of the Aditya Birla Group, ranks among the world’s largest producers of sustainable viscose and other MMCF fibres. The company operates ten pulp and fibre manufacturing sites globally and applies closed loop production technologies that optimise water use, chemical recovery, and energy efficiency. Five advanced research centres support continuous product innovation and pilot scale development, enabling faster adoption of next generation sustainable fibres.

Executives said the cooperation aligns closely with Birla Cellulose’s long term sourcing strategy and customer demand for traceable and sustainability focused fibre solutions. Circulose brings a patented recycling process that converts discarded cotton rich textiles into high quality dissolving pulp suitable for fibre production. The Swedish company has received global recognition for its innovation credentials and circular business model.

The collaboration arrives at a time when the global textile industry faces increasing regulatory and brand pressure to improve circularity. The Ellen MacArthur Foundation estimates less than 1% of textile waste is currently recycled into new fibres, despite global fibre consumption exceeding 120 million tonnes annually. Partnerships that integrate recyclers and fibre producers are considered essential to closing this gap at scale.

India’s textile and apparel sector, valued at over US$165 billion, continues to strengthen its sustainability roadmap as exports target US$100 billion by 2030. Agreements such as this signal how fibre innovation and international collaboration can support that ambition while reducing environmental impact.

Industry observers expect the Birla Cellulose Circulose partnership to encourage wider adoption of recycled MMCF fibres and set a benchmark for transparent and resilient circular supply chains.

Executives said the cooperation aligns closely with Birla Cellulose’s long term sourcing strategy and customer demand for traceable and sustainability focused fibre solutions. Circulose brings a patented recycling process that converts discarded cotton rich textiles into high quality dissolving pulp suitable for fibre production. The Swedish company has received global recognition for its innovation credentials and circular business model.

If you wish to Subscribe to Textile Excellence Print Edition, kindly fill in the below form and we shall get back to you with details.